Wissenschaft

Der Exzellenzcluster POLiS erforscht neue Batteriematerialien und Technologiekonzepte für eine leistungsfähige und nachhaltige Speicherung elektrischer Energie. Ziel des Clusters ist es, Elektrodenmaterialien und Elektrolyte zu entwickeln, die nachhaltige Systeme auf der Basis von Na-, Mg-, Zn-, Ca-, Al- und Cl-Ionen ermöglichen. Größere Hürden für Entwicklung und Einsatz von Post-Lithium-Systemen und damit die Legitimation für unsere Forschung sind:

- Niedrige Mobilität von Ionen in Festkörpern und Flüssigkeiten

- Fehlen maßgeschneiderter Materialgrenzflächen mit geeigneten Ladungstransfer-Eigenschaften

- Schnelle Alterung von Aktivmaterialien und Elektrolyt

- Unzureichende Reversibilität bei Be- und Entladeprozessen

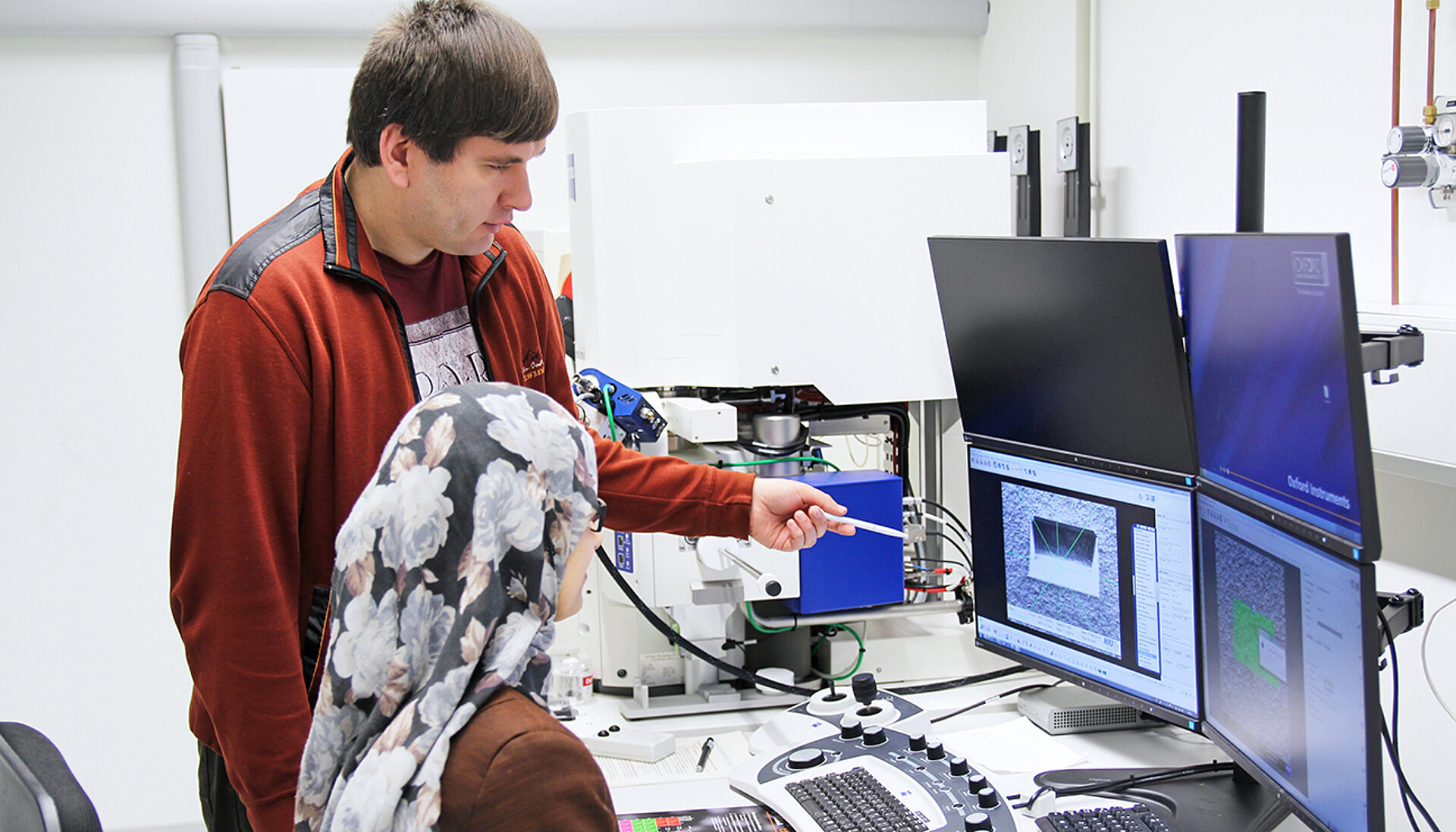

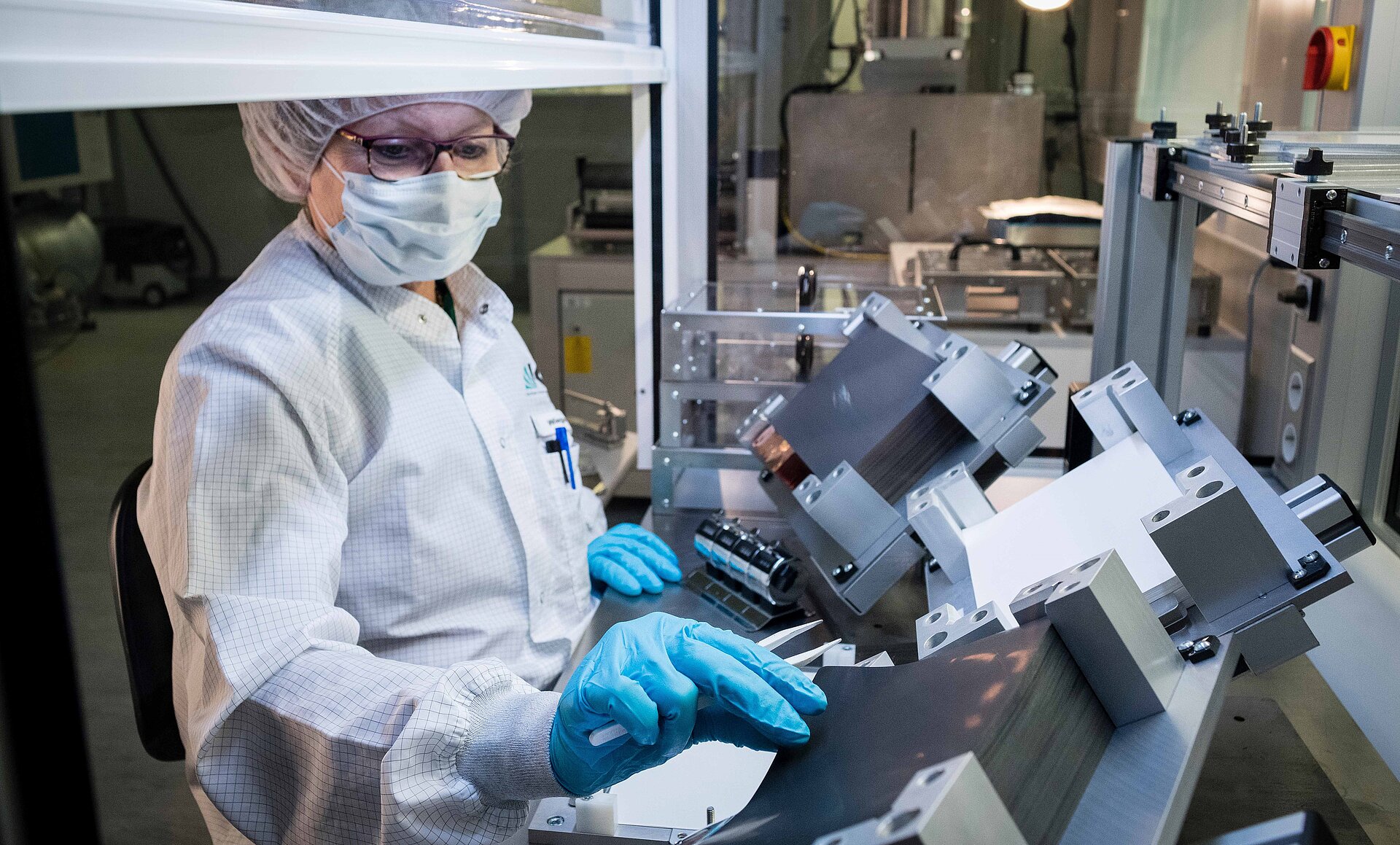

ZSW/ Elvira Eberhardt

ZSW/ Elvira Eberhardt

Kooperationen

Die Mitglieder des Clusters repräsentieren eine der stärksten Gruppen weltweit mit einem einzigartigen Portfolio an Kompetenzen, die für die Forschung und Entwicklung von Post-Li-Batterien relevant und notwendig sind. Die Zusammenarbeit mit nationalen und internationalen Partnern erfolgt sowohl auf der gegenseitigen Ebene direkter Kontakte zwischen den Forschern als auch über institutionalisierte Kooperationen. Ein wichtiger Aspekt ist der aktive Austausch von Personal zur Förderung wissenschaftlicher Exzellenz und gemeinsamer Projekte.

Bei Interesse an einer Kooperation mit uns, wenden Sie sich bitte an unseren Sprecher Maximilian Fichtner (+49 (0)731 50 34201, m.fichtner@kit.edu) oder direkt an einen unserer Principal Investigator, deren Kontaktdaten Sie hier finden.

Daniel Messling

Daniel Messling

Markus Breig

Markus Breig

Die Arbeiten im Cluster sind in vier thematischen Säulen (Research Units) organisiert, die die zentralen Komponenten eines elektrochemischen Systems abbilden: Elektrodenmaterialien, Elektrolyte, Grenzflächen, sowie Integration und nachhaltige Zellentwicklung. Der Cluster verfolgt einen multidisziplinären Ansatz, der Nass- und Festkörperchemie, Elektrochemie, atomistische und Kontinuums-Modellierung mit Chemieingenieurwesen und Verfahrenstechnik verbindet. Die erarbeiteten Konzepte werden auf Batterie-Vollzellen übertragen, um sie auf Leistungsfähigkeit, Nachhaltigkeit und Sicherheit zu überprüfen. Es gibt eine rasch steigende Nachfrage für zukünftige Batterien, die Folgendes umfassen und unsere Forschung definieren:

- Nachhaltige Materialien und Herstellungsverfahren

- Erhöhte volumetrische/gravimetrische Energiedichte

- Eigensichere Konstruktion

- Lange Betriebs- und Haltbarkeitsdauer

- Niedriger Preis pro kWh

Elvira Eberhardt

Elvira Eberhardt

Karriereförderung von Nachwuchsforscher*innen

Die Karriereaussichten von Nachwuchsforscher*innen bei POLiS sind aufgrund der hohen wissenschaftlichen und industriellen Relevanz des Forschungsprogramms hervorragend, was sich in einer hohen Nachfrage nach gut ausgebildetem Fachpersonal in den relevanten Branchen, etwa bei Batteriematerialzulieferern oder in der Automobil- und Elektronikindustrie, zeigt.

Der Cluster bietet in Zusammenarbeit mit der Graduiertenschule (GS-EES) ein strukturiertes Qualifizierungsprogramm an. Weitere Informationen finden Sie hier. Wir freuen uns auf Ihre aussagekräftige Initiativbewerbung, die Sie bitte an den entsprechenden Principal Investigator richten, der sich mit dem für Sie interessanten Forschungsgebiet beschäftigt.

Struktur

Forschungsthemen

Research Unit A (Electrode Materials)

Electrode materials define and limit the amount of energy that can be stored per weight and volume of a battery. Our goal is to identify, synthesize and test new high-capacity post-lithium storage materials and thereby gain an even deeper understanding of their functionality.

Spokesperson

Work Package A.1 – Monovalent ions

This work package is essential for reaching the overall goal to deliver large-format SIBs with high performance and to provide suitable materials and electrodes for other work packages. The focus is on layered oxides for positive electrode materials and on carbon-based negative electrodes, investigated in a comprehensive interdisciplinary approach.

Work Package A.2 – Multivalent Ions

This WP focuses on the development of electrode materials for battery chemistries based on multivalent ions (Al, Ca, Mg). The main activities aim at designing and synthesizing new or improved electrode materials. Scope of this WP is to the shed light on transport and kinetics descriptors of multivalent ions into solids by combining experimental and theoretical approaches in order to rationalize the further improvement of the proposed materials.

Work Package A.3 – Anionic Systems

The work package ‘Anionic Systems’ aims to synthesize novel electrode materials and investigate them both experimentally and theoretically. Also it will provide an overview about the interphase formation mechanism in CIB’s. Overall, this work package bridges missing links between electrode, electrolyte in chloride ion batteries and could pave way for the acceleration of research efforts on anionic batteries across the research community.

Research Unit B (Electrolyte)

Electrolytes enable the transport of electrically charged particles (ions) between the two electrodes of a battery. The main objective is the identification, synthesis and testing of new, stable and highly efficient liquid or solid transfer systems for post-lithium-ions.

Spokespersons

Work Package B.1 – Liquid Electrolytes

Any battery needs an appropriate electrolyte. Thus, the electrolyte is a key component as it connects both electrodes and allows an ionic and electronic communication between both. While at the electrodes ions are either intercalated in an existing structure or converted electrochemically by charge transfer processes, the development of suitable electrolytes faces various challenges, including stability, integrity, SEI formation processes, as well as charge and ion conductivity. This work package aims at the development of liquid electrolytes with high ionic conductivities and chemical and electrochemical stability. To tackle this challenge, different activities have been identified with the goal to synthesize and test new liquid electrolytes for mono- as well as multi-valent ions, to elucidate the mechanisms of ionic transport in these systems and to deduce strategies for better electrolytes.

Work Package B.2 – Solid Electrolytes

Solid-state batteries are considered as the ultimate solution of safety and stability issues, and their exploration and development will be a long-term enterprise. As necessary materials´ basis, solid electrolytes with a combination of various properties need to be developed, of which the high ionic conductivity (combined with low electronic conductivity), the (kinetic) stability in contact with electrode materials and their mechanical properties are important “key performance indicators”. This WP aims to be the cental WP of POLIS to explore, understand, characterize and test solid electrolytes for post-lithium systems.

Research Unit C (Interfaces)

We aim to understand the formation and nature of interfaces that form within a post-Li battery - e.g. at the contact between electrode and liquid or solid electrolyte. Their microstructure and chemical composition have a decisive influence on the interface processes within the battery and thus determine, among other things, its performance and longevity.

Spokespersons

Work Package C.1 – Structure, Function and Morphology at Metal Electrodes

Metal deposition/dissolution and SEI formation at different metal electrodes will be investigated by various experimental methods in order to obtain detailed mechanistic understanding of the underlying processes, reaching from the charge transfer processes across the interphase to structure formation and morphological changes, SEI formation and side processes like electrolyte decomposition. The experimental studies will be conducted in strong collaboration with theoretical investigations spanning from atomistic investigations of elementary processes to MD simulations and modelling on different length scales. The work program will focus on exemplary studies on a limited number of systems, e.g., Na, Mg and Al deposition from prototypical electrolytes to ensure comparability of the results obtained from different methods.

Work Package C.2 – Structure, Function and Morphology at Carbon Electrodes

This work package aims to get a holistic knowledge about ongoing reactions and kinetics at carbon anodes. To get maximum knowledge gain, we focus in our work on commonly defined carbon systems. The whole available POLiS expertise will be used to clarify ongoing atomic processes within the electrode as well as on the electrode surface considering SEI formation due to electrolyte decomposition during cycling. Only through a complete description and holistic understanding of the electrode behavior, it is possible to improve the electrodes in terms of performance and long cycling stability. A targeted added value is also developed from the methodology of how the individual analysis techniques can be brought together synergistically in order to obtain new, deeper, comprehensive insights into SEI on electrode surfaces. The knowledge gained from the selected model system (SIB) can be transferred to other, new battery systems inside and outside the POLiS cluster and can make a targeted contribution to improving the interface kinetics of next-generation batteries.

Work Package C.3 – Positive Electrodes

For positive electrodes with both solid and liquid electrolytes, the transfer processes at interfaces are decisive for the overall performance of the battery. Interfacial reactions at equilibrium and at various operation states, ion migration kinetics, the role of grain and phase boundaries and dendrite formation are all important aspects that require more indepth investigations to develop a better description of these processes and an understanding of their role in battery performance. Furthermore, interfacial processes are key to understand CEI formation and material degradation. The aim is to use this knowledge in order to optimize kinetics and to suppress degradation processes.

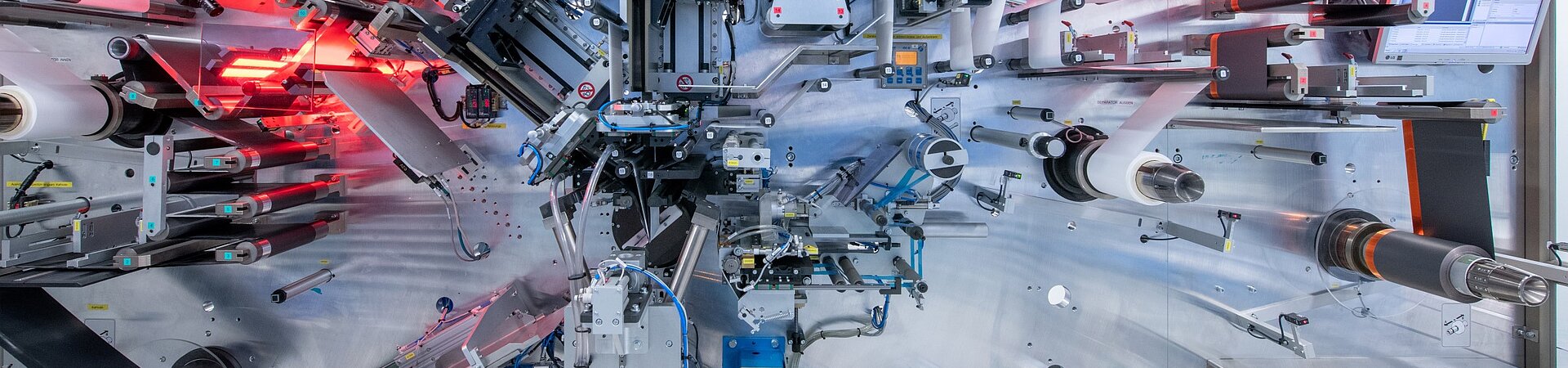

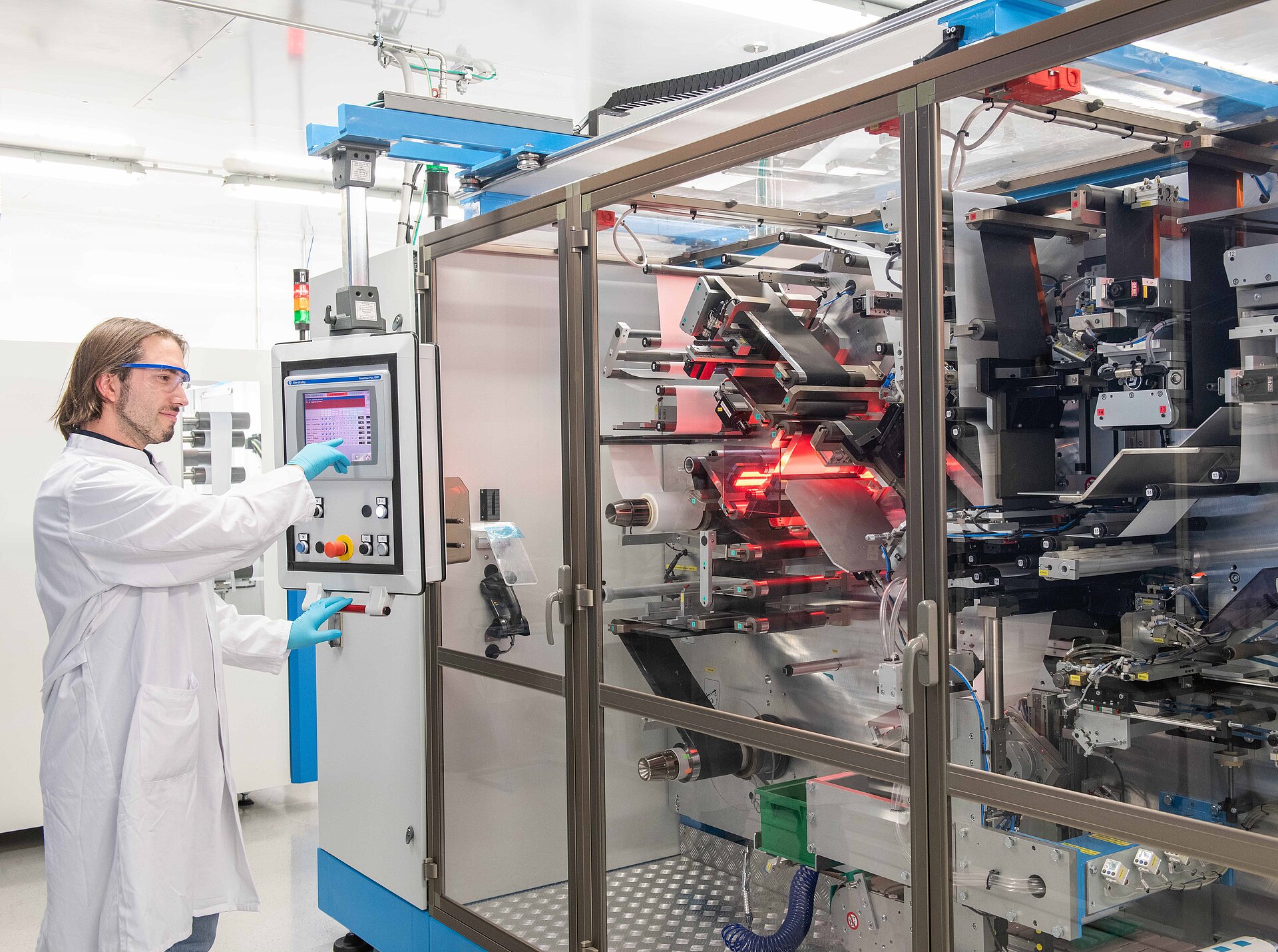

Research Unit D (Integration and Sustainable Cell Engineering)

Up-scaling of materials synthesis and cell construction, studies on the production capability of new technical approaches, assessment of cell safety and life cycle analyses of new technologies will pave the way for technology transfer. Central research data management and the development of automated data analysis tools will flank all work in the Cluster, set standards for the handling of research data and enable integrative, cross-research field data analysis, which we hope will lead to new insights in battery research.

Spokespersons

Work Package D.1 – Cell Design & Production

It intends to develop complete processing chains for post-Li systems including the scale-up of materials production, making electrode and cell manufacturing more sustainable and reliable, and the development of material-process-models to generate a deep understanding of the material behavior during processing. WP D1 is therefore, a very interdisciplinary research unit, where chemists, material scientists and process engineers tackle the complex tasks to enable the best performance from new materials in cells by developing the optimal conditions for the material, such as structure of the material, material integrity within the electrode, and overall electrode design, including its further processing up to optimal cell assembly. Another focus is on sustainable electrode and battery production through tailored manufacturing strategies depending on the material, components and composition. In the current phase, the results obtained in the material and process development activities to date are to be combined in order to lead to high-performance POLiS cells with high capacity.

Work Package D.2 – Demonstrator Cell

This WP addresses projects where the most promising post-lithium chemistries developed in POLiS (either material synthesis or its processing) are scaled up to the pouch cell level. On the one hand, a prototype lab-pouch cell serves as a proof of principle for poorly developed cell chemistries (e.g., Aluminum). On the other hand, full industrial-type pouch cells are used to demonstrate the performance of highly developed materials (e.g. Sodium). Na-, Mg- and Al-based chemistries will be studied in the full cell configuration to push each chemistry towards the next developmental step. The results from WP D2 have a great impact on POLiS as the POLiS demonstrator cell’s performance reflects the success of a complex and interdisciplinary research chain throughout all research units. The success of a cell chemistry as a demonstrator on pouch-cell level is the ultimate proof that all aspects of material, interphase, electrolyte material processing and engineering have successfully come together.

Work Package D.3 – Safety & Sustainability

Upscaling of both cathode materials as pouch cells are ongoing in cooperation with BaTec (IAM-ESS) and in similar manner, safety analysis on pouch cell level shall be performed and their heat generation during operation (under normal condition) shall be measured using Heat Flux sensors followed by thermal abuse tests using the Heat-Wait-Seek (HWS) method in the ARC. The sparation of reversible and irreversible heat as well as out gases anaylsis during cell-formation step and during thermal abuse will be also considered.

Also the sustainability of new materials and cell will be analysed in a prospective manner. The focus will be on Na- and Mg-Batteries and fluid and solid electrolyte and the prospective assessment of upscaled production process (including printing production process).The kind of analyses helps to improve the systems under development and prevent mismatch regrading the expectations of stakeholders and society regarding sustainability.

Research Unit X (Cross-sectional Topics)

In this research unit, innovative topics such as potassium batteries, organic redox systems, AI-supported virtual simulations or degradation are investigated. For this purpose, the competences from all other units are combined.

Spokespersons

Work Package X.1 – High-Energy Potassium Batteries

The overarching goal of this work package is to build high-energy potassium-ion batteries by combining the competences of the clusters’ four original research units to one coherent topical work plan. In recent years, the field of potassium batteries greatly benefitted from the broad knowledge base available for the related monovalent battery systems, namely lithium- and sodium-ion batteries, and accelerated the developments in this field considerably. However, the high reactivity of potassium or potassium storing active materials favours different electrolyte degradation pathways, leading to significant changes of the SEI properties and hence cycle life. It is therefore necessary to detach from established concepts of previous technologies and provide new, system-specific strategies that enable mature potassium-ion systems. Providing a holistic approach, ranging from liquid to solid electrolytes over new electrode material developments to in-depth characterization on material and cell level is a globally unique measure of the work package.

Work Package X.2 Organic Redox Systems

The aim of the WP “Organic Redox Systems” is to purposefully design, synthesize and test new functional organic materials for Post-Li storage. For this purpose, the activities in the WP will focus on two subprojects.

Project I on porphyrin based electrodes and project II on organic electrodes based on quinones and other functional groups. Project I is a further development of the already established organic electrode material of [5,15-bis-(ethynyl)-10,20-diphenylporphinato]copper(II) (CuDEPP), which has a capacity comparable to an LFP cathode, while its rate capability is comparable to that of a supercapacitor (50C). To improve the performance and stability of the post-Li cells with metal porphyrins, we will investigate the influence of different metal centers as well as side groups and introducing of novel functionalities.

In the second project, novel high capacity and high voltage n- and p-type electrodes will be synthesized. Special attention will be paid on designing organic redox materials with limited solubility in the electrolytes. The developed material will be electrochemically analyzed. Upon optimizing the electrode and selecting appropriate electrolyte, it will be tested for post-Li storage (mainly Na-, Mg-, and Ca systems). We anticipate that the work will provide fundamental understanding of the storage mechanism in organic redox systems as well as the establishment of structure-property-performance relationship in the organic electrodes which could be used toward rational and target-oriented development of organic electrodes for post-Li storage.

Work Package X.3 Degradation

This work package is of an overarching nature in POLiS, as degradation processes can reduce the performance and lifetime of all components of post-Li batteries. The majority of projects in this WP follow a rational approach to prevent or suppress degradation processes. By a careful characterization of the degradation, identification of degradation products and a thorough analysis of the origins of these degradation processes, strategies to suppress degradation shall be developed. To achieve this goal, degradation shall be studied both experimentally and theoretically on several length and time scales.

In a second approach, pulsed charging protocols shall be developed from combining a series of experimental techniques with simulation tools that allow for ultra fast charging without shortening the lifetime of post-Li batteries. From an analysis of the optimized charging protocols, also an better understanding of degradation processes shall be developed. These two complimentary approaches will together identify how degradation processes in post-Li batteries can be avoided, so that the lifetime of the batteries will be extended.

Work Package X.4 AI Enhanced Virtual Simulation Chain

Adressing the challenges in developing efficient, sustainable and robust Post-Lithium batteries requires a strongly coupled simulation approach comprising all length and times scales and a systematic coupling to data based simulation techniques. Within the POLiS clusters all necessary simulation competences are available to address this key challenge for accelerating the development of Post-Lithium batteries.

Objectives of the work package are, first, to gain an understanding of the factors underlying these structure and processes in Post-Lithium batteries on all involved length and time scales. Second, by using a vertical multi scale approach with validated algorithms and description to compute parameters that are transferred from one level to the next, the reliability of the theoretical and numerical results shall be improved and coupling to data driven simulation techniques will be developed.

Work Package X.5 Advanced Integrated Data Analysis & Descriptors

The work package addresses the advanced data analysis techniques, high-throughput simulations and the concept of deriving structure-property relationships by descriptors for post-Li battery systems. While the analysis techniques will be used to bridge results from experiments, theoreticians and simulations by data exchange, high-throughput simulations will serve as concept for parameter studies on different scales to create digital twins. With descriptors, correlations between fundamental materials properties and desired or undesired functional properties of the materials are extracted. In order to improve the efficiency of post-Li battery research within the work package as well as within the whole Cluster Kadi4Mat is strongly promoted as the research data infrastructure. Consequently, Kadi4Mat is the base for creating reusable workflows for data analysis, simulations and descriptors.

Publikationen

Publikationsliste

-

2026Predicting Air Flow in Calendered Paper Sheets from μ-CT Data: Combining Physics with Morphology

Gräfensteiner, P.; Rodriguez, A.; Leitl, P.; Baikova, E.; Fuchs, M.; Machado Charry, E.; Hirn, U.; Hilger, A.; Manke, I.; Schennach, R.; Neumann, M.; Schmidt, V.; Zojer, K.

2026. Transport in Porous Media, 153 (2), Article no: 15. doi:10.1007/s11242-025-02250-9Effect of Silicon‐Based Electrolyte Additive on the Solid‐Electrolyte Interphase of Rechargeable Mg Batteries

Guddehalli Chandrappa, S.; Karkera, G.; Dinda, S.; Löw, M.; Euchner, H.; Reupert, A.; Panja, S.; Bhattarai, M. K.; May, M. M.; Zhao-Karger, Z.; Fichtner, M.

2026. Advanced Science, 13 (2), Art.-Nr.: e10456. doi:10.1002/advs.202510456Sodium-ion battery cost projections and their impact on the global energy system transition until 2050

Keiner, D.; Jasper, F. B.; Bogdanov, D.; Lopez, G.; Peters, J. F.; Baumann, M. J.; Breyer, C.; Weil, M. R.

2026. Journal of Energy Storage, 146, 119861. doi:10.1016/j.est.2025.119861Generative Deep Learning for Advanced Battery Materials

Rajagopal, D.; Cierpka, A.; Nestler, B.; Koeppe, A. H.

2026. Batteries and Supercaps, 9 (2), e202500494. doi:10.1002/batt.202500494Tuning the upper cut-off voltage for enabling Co³⁺/Co²⁺ redox in a P2/P3/spinel composite cathode material for sodium-ion batteries: An in operando study

Thottungal, A.; Surendran, A.; Enale, H.; Sarapulova, A.; Ganesan, M.; Murugan, P.; Mangold, S.; Dolotko, O.; Knapp, M.; Dixon, D.; Bhaskar, A.

2026. Journal of Power Sources, 662, Article no: 238803. doi:10.1016/j.jpowsour.2025.238803 -

2025Batteriesysteme der Zukunft (aktualisiert)

Baumann, M.; Weil, M.

2025. Verlag des Ita Wegman Instituts (ITA)A Bifunctional Iron‐Nickel Oxygen Reduction/Oxygen Evolution Catalyst for High‐Performance Rechargeable Zinc–Air Batteries

Chen, Z.; Cheng, W.; Cao, K.; Jin, M.; Rahali, S.; Chala, S. A.; Ebrahimi, E.; Ma, N.; Liu, R.; Lakshmanan, K.; Chang, C.-Y.; Cheung, C.-C.; Luo, H.; Wang, Y.; Hwang, B. J.; Streb, C.

2025. Small, 21 (3). doi:10.1002/smll.202409161Semantic Resources for Managing Knowledge in Battery Research

Clark, S.; Battaglia, C.; Castelli, I. E.; Flores, E.; Gold, L.; Punckt, C.; Stier, S.; Veit, P.

2025. ChemSusChem. doi:10.1002/cssc.202500458Comprehensive performance evaluation and sustainability ranking of battery technologies based on hesitant intuitionistic fuzzy linguistic decision-making

Das, S.; Baumann, M.; Weil, M.

2025. Energy Conversion and Management, 328, Article no: 119594. doi:10.1016/j.enconman.2025.119594Role of Desolvation upon the Sodiation of Hard Carbon in Sodium-Ion Batteries: A Microcalorimetric Study of the Sodiation Entropy

Derr, L.; Lang, M.; Palanisamy, K.; Kranz, C.; Schuster, R.

2025. The Journal of Physical Chemistry C, 129 (8), 4025–4031. doi:10.1021/acs.jpcc.4c08586Calcium Chemistry as A New Member of Post‐Lithium Battery Family: What Can We Learn from Sodium and Magnesium Systems

Li, Z.; Cui, S.; Häcker, J.; Nojabaee, M.; Fichtner, M.; Cui, G.; Zhao-Karger, Z.

2025. Angewandte Chemie - International Edition, 64 (5), Art.-Nr.: e202415942. doi:10.1002/anie.202415942Simultaneously improving sodium ionic conductivity and dendrite behavior of NaSICON ceramics by grain-boundary modification

Liu, L.; Ma, Q.; Zhou, X.; Ding, Z.; Grüner, D.; Kübel, C.; Tietz, F.

2025. Journal of Power Sources, 626, 235773. doi:10.1016/j.jpowsour.2024.235773How reference electrodes improve our understanding of degradation processes in half and full cell potassium-ion battery setups

Panasenko, I.; Bäuerle, M.; Jeschull, F.

2025. Electrochimica Acta, 513, 145551. doi:10.1016/j.electacta.2024.145551Synthesis, Structural Analysis, and Degradation Behavior of Potassium Tin Chloride as Chloride‐Ion Batteries Conversion Electrode Material

Panja, S.; Miao, Y.; Döhn, J.; Choi, J.; Fleischmann, S.; Guddehalli Chandrappa, S.; Diemant, T.; Groß, A.; Karkera, G.; Fichtner, M.

2025. Advanced Functional Materials, 35 (3), Art.-Nr.: 2413489. doi:10.1002/adfm.202413489Redox Self‐Equilibration in Molecular Vanadium Oxide Mixtures Enables Multi‐Electron Storage

Remmers, M.; Mashtakov, B.; Repp, S.; Rein, A. S. J.; Wang, K.; Anjass, M.; Chen, Z.; Carrella, L. M.; Rentschler, E.; Streb, C.

2025. Angewandte Chemie International Edition, 64 (2). doi:10.1002/anie.202418864Probing the Properties of Locally Formed Solid Electrolyte Interphases on Hard Carbon Anodes

Saleh, S.; Daboss, S.; Philipp, T.; Schäfer, D.; Rohnke, M.; Kranz, C.

2025. ChemElectroChem, 12 (10), e202400707. doi:10.1002/celc.202400707Exploring the possibility of aluminum plating/stripping from a non‐corrosive Al(OTf)3‐based electrolyte

Talari, M.; Sarapulova, A.; Zemlyanushin, E.; Sabi, N.; Hofmann, A.; Trouillet, V.; Dsoke, S.

2025. Batteries & Supercaps, 8 (1), Art.-Nr.: 202400317. doi:10.1002/batt.202400317How Do Organic Batteries Work? Theoretical and Design Principles of Electrode Materials for All‐Organic Batteries

Wessling, R.; Penert, P.; Esser, B.

2025. Advanced Energy Materials, 15 (17), Art.-Nr.: 2500150. doi:10.1002/aenm.202500150Decomposition of Binary Mixtures of DMC/EC, EMC/EC, and DEC/EC on Potassium Surfaces; GC, XPS, and Calculation

Wildersinn, L.; Stottmeister, D.; Jeschull, F.; Groß, A.; Hofmann, A.

2025. ACS Applied Materials & Interfaces, 17 (6), 10055–10072. doi:10.1021/acsami.4c17461Dissolution of molybdenum current collector as Crucial and Undesired process in aluminum batteries

Zemlyanushin, E.; Schwarz, B.; Dsoke, S.

2025. Journal of Power Sources, 633, 236458. doi:10.1016/j.jpowsour.2025.236458LISA: A Lithium-Ion Solid-State Assistant using large language models for knowledge defragmentation in battery science and beyond

Zhao, Y.; Hansen, A.-L.; Dahlhaus, A.; Brandt, N.; Selzer, M.; Koeppe, A.; Nestler, B.; Knapp, M.; Ehrenberg, H.

2025. Materials Today Communications, 45, Art.-Nr.: 112380. doi:10.1016/j.mtcomm.2025.112380 -

2024Pd‐Catalyzed Oxidative C−H Arylation of (Poly)fluoroarenes with Aryl Pinacol Boronates and Experimental and Theoretical Studies of its Reaction Mechanism

Budiman, Y. P.; Putra, M. H.; Ramadhan, M. R.; Hannifah, R.; Luz, C.; Ghafara, I. Z.; Rustaman, R.; Ernawati, E. E.; Mayanti, T.; Groß, A.; Radius, U.; Marder, T. B.

2024. Chemistry – An Asian Journal, 19 (8), Art.-Nr. e202400094. doi:10.1002/asia.202400094π‐Conjugated Metal Free Porphyrin as Organic Cathode for Aluminum Batteries

Chowdhury, S.; Sabi, N.; Rojano, R. C.; Le Breton, N.; Boudalis, A. K.; Klayatskaya, S.; Dsoke, S.; Ruben, M.

2024. Batteries & Supercaps, 7 (4), Art.-Nr.: e202300285. doi:10.1002/batt.202300285Influence of Electrode Structuring Techniques on the Performance of All‐Solid‐State Batteries

Clausnitzer, M.; Danner, T.; Prifling, B.; Neumann, M.; Schmidt, V.; Latz, A.

2024. Batteries & Supercaps, 7 (4), Art.-Nr.: e202300522. doi:10.1002/batt.202300522Elucidating Gas Evolution of Prussian White Cathodes for Sodium‐ion Battery Application: The Effect of Electrolyte and Moisture

Dreyer, S. L.; Maddar, F. M.; Kondrakov, A.; Janek, J.; Hasa, I.; Brezesinski, T.

2024. Batteries & Supercaps, 7 (4), e202300595. doi:10.1002/batt.202300595Effect of Chloride Ions on the Electrochemical Performance of Magnesium Metal‐Organic‐Frameworks‐Based Semi‐Solid Electrolytes

Elnagar, M. M.; Hassan, H. K.; Kibler, L. A.; Jacob, T.

2024. Batteries and Supercaps, e202400420. doi:10.1002/batt.202400420Systematic review of scale-up methods for prospective life cycle assessment of emerging technologies

Erakca, M.; Baumann, M.; Helbig, C.; Weil, M.

2024. Journal of Cleaner Production, 451, 142161. doi:10.1016/j.jclepro.2024.142161MgO coated P

Gauckler, C.; Kucinskis, G.; Pfeiffer, L. F.; Abdellatif, A. A.; Tang, Y.; Kübel, C.; Maroni, F.; Gong, R.; Wohlfahrt-Mehrens, M.; Axmann, P.; Marinaro, M.

2024. Journal of Power Sources Advances, 25, 100135. doi:10.1016/j.powera.2024.100135A Stable High-Potential Na₇V₄(P₂O₇)₄(PO₄) Cathode for Sodium-Ion Batteries Developed from a Water-Based Slurry

Gong, R.; Maroni, F.; Marinaro, M.

2024. Journal of The Electrochemical Society, 171 (4), 040508. doi:10.1149/1945-7111/ad36e8In Situ Monitoring of the Al(110)‐[EMImCl] : AlCl 3 Interface by Reflection Anisotropy Spectroscopy

Guidat, M.; Rahide, F.; Löw, M.; Kim, J.; Ehrenberg, H.; Dsoke, S.; May, M. M.

2024. Batteries & Supercaps, 7 (1), Art.-Nr.: e202300394. doi:10.1002/batt.202300394Effect of Guest Solvents on the Ionic Conductivity and Electrochemical Performance of Metal‐Organic Framework‐Based Magnesium Semi‐Solid Electrolytes

Hassan, H. K.; Hoffmann, P.; Jacob, T.

2024. ChemSusChem, 17 (5), Art.Nr.: e202301362. doi:10.1002/cssc.202301362Detection of Charge‐Neutral Near‐Equilibrium Processes at Na‐Metal Electrodes by Electrochemical Microcalorimetry

Karcher, F.; Uhl, M.; Geng, T.; Jacob, T.; Schuster, R.

2024. Advanced Energy Materials, 14 (3), Art.-Nr.: 2302241. doi:10.1002/aenm.202302241Impact of Nano‐sized Inorganic Fillers on PEO‐based Electrolytes for Potassium Batteries

Khudyshkina, A. D.; Rauska, U.-C.; Butzelaar, A. J.; Hoffmann, M.; Wilhelm, M.; Theato, P.; Jeschull, F.

2024. Batteries and Supercaps, 7 (1), Art.-Nr.: e202300404. doi:10.1002/batt.202300404Studies on 3D printing of Na3Zr2Si2PO12 ceramic solid electrolyte through Fused Filament Fabrication

Kutlu, A. C.; Nötzel, D.; Hofmann, A.; Ziebert, C.; Seifert, H. J.; Mohsin, I. U.

2024. Electrochimica Acta, 503, Art.-Nr.: 144881. doi:10.1016/j.electacta.2024.144881Cover Feature: 3D Printing of Na1.3Al0.3Ti1.7(PO4)3 Solid Electrolyte via Fused Filament Fabrication for All-Solid-State Sodium-Ion Batteries (Batteries & Supercaps 1/2024)

Kutlu, A. C.; Nötzel, D.; Ziebert, C.; Seifert, H. J.; Ul Mohsin, I.

2024. Batteries & Supercaps, 7 (1), Art.-Nr.: e202300577. doi:10.1002/batt.2023005773D Printing of Na

Kutlu, A. C.; Nötzel, D.; Ziebert, C.; Seifert, H. J.; Mohsin, I. U.

2024. Batteries & Supercaps, 7 (1), e202300357. doi:10.1002/batt.202300357The relevance of structural variability in the time-domain for computational reflection anisotropy spectroscopy at solid–liquid interfaces

Leist, J.; Kim, J.; Euchner, H.; May, M. M.

2024. Journal of Physics: Condensed Matter, 36 (18), Art.-Nr.: 185002. doi:10.1088/1361-648X/ad215bMagnesium and Aluminum in Contact with Liquid Battery Electrolytes: Ion Transport through Interphases and in the Bulk

Löw, M.; Grill, J.; May, M. M.; Popovic-Neuber, J.

2024. ACS Materials Letters, 6 (11), 5120–5127. doi:10.1021/acsmaterialslett.4c01589Nucleation Mechanisms of Electrodeposited Magnesium on Metal Substrates

Löw, M.; Maroni, F.; Zaubitzer, S.; Dongmo, S.; Marinaro, M.

2024. Batteries & Supercaps, 7 (11). doi:10.1002/batt.202400250Dualism of Remarkable Magnesium Ion Conduction with Low Activation Energy over a Wide Temperature Range versus Limited Stability of the Hybrid Composite Electrolyte Mg‐MOF‐74/Mg X 2 /Propylene Carbonate

Maile, R.; Wei, Z.; Achazi, A. J.; Wang, K.; Henkel, P.; Mollenhauer, D.; Janek, J.; Müller-Buschbaum, K.

2024. Advanced Energy and Sustainability Research, 5 (9), Art.-Nr.: 2300288. doi:10.1002/aesr.202300288Exploring the reactivity of Na₃V₂(PO4)₃/C and hard carbon electrodes in sodium-ion batteries at various charge states

Mohsin, I. U.; Hofmann, A.; Ziebert, C.

2024. Electrochimica Acta, 487, Article no: 144197. doi:10.1016/j.electacta.2024.144197Stochastic 3D Modeling of Nanostructured NVP/C Active Material Particles for Sodium‐Ion Batteries

Neumann, M.; Philipp, T.; Häringer, M.; Neusser, G.; Binder, J. R.; Kranz, C.

2024. Batteries & Supercaps, 7 (4). doi:10.1002/batt.202300409Deposition of Sodium Metal at the Copper‐NaSICON Interface for Reservoir‐Free Solid‐State Sodium Batteries

Ortmann, T.; Fuchs, T.; Eckhardt, J. K.; Ding, Z.; Ma, Q.; Tietz, F.; Kübel, C.; Rohnke, M.; Janek, J.

2024. Advanced Energy Materials, 14 (15), Art.-Nr.: 2302729. doi:10.1002/aenm.202302729Microscopic and Spectroscopic Analysis of the Solid Electrolyte Interphase at Hard Carbon Composite Anodes in 1 M NaPF

Palanisamy, K.; Daboss, S.; Romer, J.; Schäfer, D.; Rohnke, M.; Flowers, J. K.; Fuchs, S.; Stein, H. S.; Fichtner, M.; Kranz, C.

2024. Batteries and Supercaps, Art.Nr.: e202300482. doi:10.1002/batt.202300482Spray‐coated Hard Carbon Composite Anodes for Sodium‐Ion Insertion

Palanisamy, K.; Daboss, S.; Schäfer, D.; Rohnke, M.; Derr, L.; Lang, M.; Schuster, R.; Kranz, C.

2024. Batteries and Supercaps, 7 (1), Art.-Nr.: e202300402. doi:10.1002/batt.202300402Modification of Al Surface via Acidic Treatment and its Impact on Plating and Stripping

Rahide, F.; Palanisamy, K.; Flowers, J. K.; Hao, J.; Stein, H. S.; Kranz, C.; Ehrenberg, H.; Dsoke, S.

2024. ChemSusChem, 17 (5), Art.Nr.: e202301142. doi:10.1002/cssc.202301142Improving rechargeable magnesium batteries through dual cation co-intercalation strategy

Roy, A.; Sotoudeh, M.; Dinda, S.; Tang, Y.; Kübel, C.; Groß, A.; Zhao-Karger, Z.; Fichtner, M.; Li, Z.

2024. Nature Communications, 15 (1), Art.-Nr.: 492. doi:10.1038/s41467-023-44495-2PFAS-Free Energy Storage: Investigating Alternatives for Lithium-Ion Batteries

Savvidou, E. K.; Rensmo, A.; Benskin, J. P.; Schellenberger, S.; Hu, X.; Weil, M.; Cousins, I. T.

2024. Environmental Science & Technology, 58 (50), 21908–21917. doi:10.1021/acs.est.4c06083Multiscale Investigation of Sodium‐Ion Battery Anodes: Analytical Techniques and Applications

Schäfer, D.; Hankins, K.; Allion, M.; Krewer, U.; Karcher, F.; Derr, L.; Schuster, R.; Maibach, J.; Mück, S.; Kramer, D.; Mönig, R.; Jeschull, F.; Daboss, S.; Philipp, T.; Neusser, G.; Romer, J.; Palanisamy, K.; Kranz, C.; Buchner, F.; Behm, R. J.; Ahmadian, A.; Kübel, C.; Mohammad, I.; Samoson, A.; Witter, R.; Smarsly, B.; Rohnke, M.

2024. Advanced Energy Materials, 14 (15), Art.-Nr.: 2302830. doi:10.1002/aenm.202302830Conjugated Polyimidazole Nanoparticles as Biodegradable Electrode Materials for Organic Batteries

Schuster, P. A.; Uhl, M.; Kissmann, A.-K.; Jansen, F.; Geng, T.; Ceblin, M. U.; Spiewok, S.; Rosenau, F.; Jacob, T.; Kuehne, A. J. C.

2024. Advanced Electronic Materials, 10 (4), Art.-Nr.: 2300464. doi:10.1002/aelm.202300464Magnetic Single‐Ion Anisotropy and Curie‐Weiss Behaviour of Mg₃V₄(PO₄)₆

Schwarz, B. C.; Fu, Q.

2024. European Journal of Inorganic Chemistry, 27 (18), e202400162. doi:10.1002/ejic.202400162Ion Mobility in Crystalline Battery Materials

Sotoudeh, M.; Baumgart, S.; Dillenz, M.; Döhn, J.; Forster-Tonigold, K.; Helmbrecht, K.; Stottmeister, D.; Groß, A.

2024. Advanced Energy Materials, 14 (4), Art.Nr.: 2302550. doi:10.1002/aenm.202302550From Powder to Pouch Cell: Setting up a Sodium‐Ion Battery Reference System Based on Na₃V₂(PO₄)₃/C and Hard Carbon

Stüble, P.; Müller, C.; Bohn, N.; Müller, M.; Hofmann, A.; Akçay, T.; Klemens, J.; Koeppe, A.; Kolli, S.; Rajagopal, D.; Geßwein, H.; Schabel, W.; Scharfer, P.; Selzer, M.; Binder, J. R.; Smith, A.

2024. Batteries & Supercaps, 7 (12), e202400406. doi:10.1002/batt.202400406Enabling Long‐term Cycling Stability of Na₃V₂(PO₄)₃ /C vs . Hard Carbon Full‐cells

Stüble, P.; Müller, C.; Klemens, J.; Scharfer, P.; Schabel, W.; Häringer, M.; Binder, J. R.; Hofmann, A.; Smith, A.

2024. Batteries and Supercaps, 7 (2), Art.-Nr. e202300375. doi:10.1002/batt.202300375Recent developments and future prospects of magnesium–sulfur batteries

Wang, L.; Riedel, S.; Drews, J.; Zhao-Karger, Z.

2024. Frontiers in Batteries and Electrochemistry, 3. doi:10.3389/fbael.2024.1358199Challenges and Progress in Anode‐Electrolyte Interfaces for Rechargeable Divalent Metal Batteries

Wang, L.; Riedel, S.; Zhao-Karger, Z.

2024. Advanced Energy Materials, 14 (38), Art.-Nr.: 2402157. doi:10.1002/aenm.202402157Exploration of the Lithium Storage Mechanism in Monoclinic Nb

Xue, X.; Asenbauer, J.; Eisenmann, T.; Lepore, G. O.; d’Acapito, F.; Xing, S.; Tübke, J.; Mullaliu, A.; Li, Y.; Geiger, D.; Biskupek, J.; Kaiser, U.; Steinle, D.; Birrozzi, A.; Bresser, D.

2024. Small Structures, 5 (6), Art.-Nr.: 2300545. doi:10.1002/sstr.202300545Static theoretical investigations of organic redox active materials for redox flow batteries

Zaichenko, A.; Achazi, A. J.; Kunz, S.; Wegner, H. A.; Janek, J.; Mollenhauer, D.

2024. Progress in Energy, 6, Article no: 012001. doi:10.1088/2516-1083/ad0913Unravelling the peculiar role of Co and Al in highly Ni-rich layered oxide cathode materials

Zhang, J.; Wang, S.; Yang, X.; Liu, Y.; Wu, Z.; Li, H.; Indris, S.; Ehrenberg, H.; Hua, W.

2024. Chemical Engineering Journal, 484, Article no: 149599. doi:10.1016/j.cej.2024.149599Modeling storage particle delamination and electrolyte cracking in cathodes of solid state batteries

Zhang, T.; Kamlah, M.; McMeeking, R. M.

2024. Journal of the Mechanics and Physics of Solids, 185, 105551. doi:10.1016/j.jmps.2024.105551 -

2023Reversible Electrodeposition of Potassium‐bridged Molecular Vanadium Oxides: A New Approach Towards Multi‐Electron Storage

Arya, N.; Philipp, T.; Greiner, S.; Steiner, M.; Kranz, C.; Anjass, M.

2023. Angewandte Chemie International Edition, 62 (35). doi:10.1002/anie.202306170Batteriesysteme der Zukunft - Foresight & Technikfolgenabschätzung: Monitoring November 2023

Baumann, M.; Weil, M.

2023. Verlag des Ita Wegman Instituts (ITA)Rhombohedral (R

Baumgart, S.; Sotoudeh, M.; Groß, A.

2023. Batteries & Supercaps, 6 (12), e202300294. doi:10.1002/batt.202300294Societal acceptability of large stationary battery storage systems

Baur, D.; Baumann, M. J.; Stuhm, P.; Weil, M.

2023. Energy Technology, 11 (6), Art.-Nr.: 2201454. doi:10.1002/ente.202201454Multi‐Component PtFeCoNi Core‐Shell Nanoparticles on MWCNTs as Promising Bifunctional Catalyst for Oxygen Reduction and Oxygen Evolution Reactions

Braun, T.; Dinda, S.; Karkera, G.; Melinte, G.; Diemant, T.; Kübel, C.; Fichtner, M.; Pammer, F.

2023. ChemistrySelect, 8 (29), Art.-Nr.: e202300396. doi:10.1002/slct.202300396The role of exact exchange on the structure of water dimer radical cation: Hydrogen bond vs hemibond

Busch, M.; Sotoudeh, M.

2023. The Journal of Chemical Physics, 159 (3), Article no: 034303. doi:10.1063/5.0153759Characterization of the solid/electrolyte interphase at hard carbon anodes via scanning (electrochemical) probe microscopy

Daboss, S.; Philipp, T.; Palanisamy, K.; Flowers, J.; Stein, H. S.; Kranz, C.

2023. Electrochimica Acta, 453, Art.-Nr.: 142345. doi:10.1016/j.electacta.2023.142345Exploring the influence of FIB processing and SEM imaging on solid-state electrolytes

Ding, Z.; Tang, Y.; Chakravadhanula, V. S. K.; Ma, Q.; Tietz, F.; Dai, Y.; Scherer, T.; Kübel, C.

2023. Microscopy, 72 (4), 326–335. doi:10.1093/jmicro/dfac064The Impact of Microstructure on Filament Growth at the Sodium Metal Anode in All‐Solid‐State Sodium Batteries

Ding, Z.; Tang, Y.; Ortmann, T.; Eckhardt, J. K.; Dai, Y.; Rohnke, M.; Melinte, G.; Heiliger, C.; Janek, J.; Kübel, C.

2023. Advanced Energy Materials, 13 (48), Art.Nr.: 2302322. doi:10.1002/aenm.202302322Closing gaps in LCA of lithium-ion batteries: LCA of lab-scale cell production with new primary data

Erakca, M.; Pinto Bautista, S.; Moghaddas, S.; Baumann, M.; Bauer, W.; Leuthner, L.; Weil, M.

2023. Journal of Cleaner Production, 384, Art.-Nr.: 135510. doi:10.1016/j.jclepro.2022.135510Reactive Metals as Energy Storage and Carrier Media

Ersoy, H.; Baumann, M.; Weil, M.; Barelli, L.; Passerini, S.

2023. Sustainable Energy Storage in the Scope of Circular Economy – Advanced Materials and Device Design. Ed.: C. Costa, 17–41, John Wiley and Sons. doi:10.1002/9781119817741.ch2Development of a Mg/O ReaxFF Potential to describe the Passivation Processes in Magnesium‐Ion Batteries

Fiesinger, F.; Gaissmaier, D.; van den Borg, M.; Beßner, J.; van Duin, A. C. T.; Jacob, T.

2023. ChemSusChem, 16 (3), Art.-Nr.: e202201821. doi:10.1002/cssc.202201821Guest Ion-Dependent Reaction Mechanisms of New Pseudocapacitive Mg

Fu, Q.; Schwarz, B.; Ding, Z.; Sarapulova, A.; Weidler, P. G.; Missyul, A.; Etter, M.; Welter, E.; Hua, W.; Knapp, M.; Dsoke, S.; Ehrenberg, H.

2023. Advanced Science, 10 (11), Art.-Nr.: 2207283. doi:10.1002/advs.202207283To be or not to be – Is MgSc2Se4 a Mg-Ion Solid Electrolyte?

Glaser, C.; Wei, Z.; Indris, S.; Klement, P.; Chatterjee, S.; Ehrenberg, H.; Zhao-Karger, Z.; Rohnke, M.; Janek, J.

2023. Advanced Energy Materials, Art.-Nr.: 2301980. doi:10.1002/aenm.202301980Challenges for ab initio molecular dynamics simulations of electrochemical interfaces

Groß, A.

2023. Current Opinion in Electrochemistry, 40, Article no: 101345. doi:10.1016/j.coelec.2023.101345Experimental and Computational Aspects of Electrochemical Reflection Anisotropy Spectroscopy : A Review

Guidat, M.; Löw, M.; Kölbach, M.; Kim, J.; May, M. M.

2023. ChemElectroChem, 10 (8), e2023000. doi:10.1002/celc.202300027Deciphering Electrolyte Degradation in Sodium-Based Batteries: The Role of Conductive Salt Source, Additives, and Storage Condition

Hashimov, M.; Hofmann, A.

2023. Batteries, 9 (11), Art.-Nr. 530. doi:10.3390/batteries9110530Asymptotic properties of one-layer artificial neural networks with sparse connectivity

Hirsch, C.; Neumann, M.; Schmidt, V.

2023. Statistics & Probability Letters, 193, Art.-Nr.: 109698. doi:10.1016/j.spl.2022.109698Revealing the Formation of Dialkyl Dioxahexane Dioate Products from Ethylene Carbonate Based Electrolytes on Lithium and Potassium Surfaces

Hofmann, A.; Müller, F.; Schöner, S.; Jeschull, F.

2023. Batteries & Supercaps, 6 (12), Art.Nr.: e202300325. doi:10.1002/batt.202300325Dynamic inconsistency between electrochemical reaction and phase transition in Na-deficient layered cathode materials

Hua, W.; Yang, X.; Wang, S.; Li, H.; Senyshyn, A.; Tayal, A.; Baran, V.; Chen, Z.; Avdeev, M.; Knapp, M.; Ehrenberg, H.; Saadoune, I.; Chou, S.; Indris, S.; Guo, X.

2023. Energy Storage Materials, 61, Article no: 102906. doi:10.1016/j.ensm.2023.102906Multivalent Cation Transport in Polymer Electrolytes – Reflections on an Old Problem

Jeschull, F.; Hub, C.; Kolesnikov, T. I.; Sundermann, D.; Hernández, G.; Voll, D.; Mindemark, J.; Théato, P.

2023. Advanced Energy Materials. doi:10.1002/aenm.202302745P3 type layered oxide frameworks: An appealing family of insertion materials for K-ion batteries

Jha, P. K.; Pralong, V.; Fichtner, M.; Barpanda, P.

2023. Current Opinion in Electrochemistry, 38, Art.-Nr.: 101216. doi:10.1016/j.coelec.2023.101216Entropic Contributions to Sodium Solvation and Solvent Stabilization upon Electrochemical Sodium deposition from Diglyme and Propylene Carbonate Electrolytes

Karcher, F.; Uhl, M.; Geng, T.; Jacob, T.; Schuster, R.

2023. Angewandte Chemie International Edition, 62 (22), e202301253. doi:10.1002/anie.202301253From lithium to potassium: Comparison of cations in poly(ethylene oxide)-based block copolymer electrolytes for solid-state alkali metal batteries

Khudyshkina, A. D.; Butzelaar, A. J.; Guo, Y.; Hoffmann, M.; Bergfeldt, T.; Schaller, M.; Indris, S.; Wilhelm, M.; Théato, P.; Jeschull, F.

2023. Electrochimica Acta, 454, Article no: 142421. doi:10.1016/j.electacta.2023.142421Atomic Layer Deposition Derived Zirconia Coatings on Ni‐Rich Cathodes in Solid‐State Batteries: Correlation Between Surface Constitution and Cycling Performance

Kitsche, D.; Tang, Y.; Hemmelmann, H.; Walther, F.; Bianchini, M.; Kondrakov, A.; Janek, J.; Brezesinski, T.

2023. Small Science, 3 (2), Art.-Nr.: 2200073. doi:10.1002/smsc.202200073Drying of Compact and Porous NCM Cathode Electrodes in Different Multilayer Architectures: Influence of Layer Configuration and Drying Rate on Electrode Properties

Klemens, J.; Burger, D.; Schneider, L.; Spiegel, S.; Müller, M.; Bohn, N.; Bauer, W.; Ehrenberg, H.; Scharfer, P.; Schabel, W.

2023. Energy Technology, 11 (8), Art.Nr.: 2300267. doi:10.1002/ente.202300267Process and Drying Behavior Toward Higher Drying Rates of Hard Carbon Anodes for Sodium‐Ion Batteries with Different Particle Sizes: An Experimental Study in Comparison to Graphite for Lithium‐Ion‐Batteries

Klemens, J.; Schneider, L.; Burger, D.; Zimmerer, N.; Müller, M.; Bauer, W.; Ehrenberg, H.; Scharfer, P.; Schabel, W.

2023. Energy Technology, 11 (8), Art.-Nr.: 2300338. doi:10.1002/ente.202300338Challenges and Opportunities for Large‐Scale Electrode Processing for Sodium‐Ion and Lithium‐Ion Battery

Klemens, J.; Wurba, A.-K.; Burger, D.; Müller, M.; Bauer, W.; Büchele, S.; Leonet, O.; Blázquez, J. A.; Boyano, I.; Ayerbe, E.; Ehrenberg, H.; Fleischer, J.; Smith, A.; Scharfer, P.; Schabel, W.

2023. Batteries & Supercaps, 6 (11), Art.Nr.: e202300291. doi:10.1002/batt.202300291Investigation of SnS₂‐rGO Sandwich Structures as Negative Electrode for Sodium‐ion and Potassium‐ion Batteries

Li, C.; Pfeifer, K.; Luo, X.; Melinte, G.; Wang, J.; Zhang, Z.; Zhang, Y.; Dong, P.; Sarapulova, A.; Ehrenberg, H.; Dsoke, S.

2023. ChemSusChem, 16 (7), e202202281. doi:10.1002/cssc.202202281Chemistry, electrochemistry, and electrochemical applications of magnesium

Li, Z.; Wang, L.; Bautista, S. P.; Weil, M.

2023. Reference Module in Chemistry, Molecular Sciences and Chemical Engineering. Ed.: J. Reedijk, Elsevier. doi:10.1016/B978-0-323-96022-9.00066-9ToF-SIMS in battery research: Advantages, limitations, and best practices

Lombardo, T.; Walther, F.; Kern, C.; Moryson, Y.; Weintraut, T.; Henss, A.; Rohnke, M.

2023. Journal of Vacuum Science & Technology A, 41 (5), Article no: 053207. doi:10.1116/6.0002850Fundamental Understanding and Quantification of Capacity Losses Involving the Negative Electrode in Sodium‐Ion Batteries

Ma, L. A.; Buckel, A.; Hofmann, A.; Nyholm, L.; Younesi, R.

2023. Advanced Science, Art.-Nr.2306771. doi:10.1002/advs.202306771Capacity losses due to solid electrolyte interphase formation and sodium diffusion in sodium-ion batteries

Ma, L. A.; Buckel, A.; Nyholm, L.; Younesi, R.

2023. Research Square. doi:10.21203/rs.3.rs-623903/v1Environmental life cycle assessment of emerging solid-state batteries: A review

Mandade, P.; Weil, M.; Baumann, M.; Wei, Z.

2023. Chemical engineering journal advances, 13, Art.-Nr.: 100439. doi:10.1016/j.ceja.2022.100439Sodium Insertion into Fe[Fe(CN) 6 ] Framework Prepared by Microwave‐Assisted Co‐Precipitation

Maroni, F.; Li, M.; Dongmo, S.; Gauckler, C.; Wohlfahrt-Mehrens, M.; Giorgetti, M.; Marinaro, M.

2023. ChemElectroChem, 10 (8), e202201070. doi:10.1002/celc.202201070New insights into Self‐discharge and Heat Generation in Magnesium Batteries

Mohsin, I. U.; Riedel, S.; Xiu, Y.; Zhao-Karger, Z.; Ziebert, C.

2023. Batteries & Supercaps, 6 (7), Art.Nr.: e202300137. doi:10.1002/batt.202300137Enabling the Electrochemical Performance of Maricite-NaMnPO4 and Maricite-NaFePO4 Cathode Materials in Sodium-Ion Batteries

Mohsin, I. U.; Schneider, L.; Yu, Z.; Cai, W.; Ziebert, C.

2023. (A. Arunachalam, Hrsg.) International Journal of Electrochemistry, 2023, Artlk. ID.: 6054452. doi:10.1155/2023/6054452Effect of self and extrinsic encapsulation on electron resilience of porous 2D polymer nanosheets

Mücke, D.; Linck, M.; Guzzinati, G.; Müller, H.; Levin, B. D. A.; Bammes, B. E.; Brouwer, R. G.; Jelezko, F.; Qi, H.; Kaiser, U.

2023. Micron, 174, Article no: 103525. doi:10.1016/j.micron.2023.103525Influences on Reliable Capacity Measurements of Hard Carbon in Highly Loaded Electrodes

Müller, C.; Wang, Z.; Hofmann, A.; Stueble, P.; Liu-Théato, X.; Klemens, J.; Smith, A.

2023. Batteries & Supercaps, 6 (11), Art.Nr.: e202300322. doi:10.1002/batt.202300322Morphology‐Dependent Influences on the Performance of Battery Cells with a Hierarchically Structured Positive Electrode**

Naumann, J.; Bohn, N.; Birkholz, O.; Neumann, M.; Müller, M.; Binder, J. R.; Kamlah, M.

2023. Batteries & Supercaps, 6 (12), Art.-Nr.: e202300264. doi:10.1002/batt.202300264A data-driven modeling approach to quantify morphology effects on transport properties in nanostructured NMC particles

Neumann, M.; Wetterauer, S. E.; Osenberg, M.; Hilger, A.; Gräfensteiner, P.; Wagner, A.; Bohn, N.; Binder, J. R.; Manke, I.; Carraro, T.; Schmidt, V.

2023. International Journal of Solids and Structures, 280, Article no: 112394. doi:10.1016/j.ijsolstr.2023.112394Open Challenges on Aluminum Triflate-Based Electrolytes for Aluminum Batteries

Rahide, F.; Zemlyanushin, E.; Bosch, G.-M.; Dsoke, S.

2023. Journal of The Electrochemical Society, 170 (3), Article no: 030546. doi:10.1149/1945-7111/acc762Conductivity experiments for electrolyte formulations and their automated analysis

Rahmanian, F.; Vogler, M.; Wölke, C.; Yan, P.; Fuchs, S.; Winter, M.; Cekic-Laskovic, I.; Stein, H. S.

2023. Scientific Data, 10 (1), Art.-Nr.: 43. doi:10.1038/s41597-023-01936-3Surface Properties‐Performance Relationship of Aluminum Foil as Negative Electrode for Rechargeable Aluminum Batteries

Sabi, N.; Palanisamy, K.; Rahide, F.; Daboss, S.; Kranz, C.; Dsoke, S.

2023. Batteries & Supercaps, 6 (11), Art.Nr.: e202300298. doi:10.1002/batt.202300298Unraveling Propylene Oxide Formation in Alkali Metal Batteries

Stottmeister, D.; Wildersinn, L.; Maibach, J.; Hofmann, A.; Jeschull, F.; Groß, A.

2023. ChemSusChem, 17 (3), Art.Nr.: e202300995. doi:10.1002/cssc.202300995On a high-capacity aluminium battery with a two-electron phenothiazine redox polymer as positive electrode

Studer, G.; Schmidt, A.; Büttner, J.; Schmidt, M.; Fischer, A.; Krossing, I.; Esser, B.

2023. Energy & Environmental Science. doi:10.1039/D3EE00235GNew Insights into Self‐Discharge and Heat Generation in Magnesium Batteries

Ul Mohsin, I.; Riedel, S.; Xiu, Y.; Zhao-Karger, Z.; Ziebert, C.

2023. Batteries & Supercaps, 6 (7), Art.-Nr.: e202300251. doi:10.1002/batt.202300251Brokering between tenants for an international materials acceleration platform

Vogler, M.; Busk, J.; Hajiyani, H.; Jørgensen, P. B.; Safaei, N.; Castelli, I. E.; Ramirez, F. F.; Carlsson, J.; Pizzi, G.; Clark, S.; Hanke, F.; Bhowmik, A.; Stein, H. S.

2023. Matter, 6 (9), 2647–2665. doi:10.1016/j.matt.2023.07.016Synergy of cations in high entropy oxide lithium ion battery anode

Wang, K.; Hua, W.; Huang, X.; Stenzel, D.; Wang, J.; Ding, Z.; Cui, Y.; Wang, Q.; Ehrenberg, H.; Breitung, B.; Kübel, C.; Mu, X.

2023. Nature Communications, 14, Art.-Nr.: 1487. doi:10.1038/s41467-023-37034-6Segmentation and morphological analysis of amyloid fibrils from cryo-EM image data

Weber, M.; Neumann, M.; Schmidt, M.; Pfeiffer, P. B.; Bansal, A.; Fändrich, M.; Schmidt, V.

2023. Journal of Mathematics in Industry, 13 (2). doi:10.1186/s13362-023-00131-8In Situ Observation of Room‐Temperature Magnesium Metal Deposition on a NASICON/IL Hybrid Solid Electrolyte

Wei, Z.; Singh, D. K.; Helmbrecht, K.; Sann, J.; Yusim, Y.; Kieser, J. A.; Glaser, C.; Rohnke, M.; Groß, A.; Janek, J.

2023. Advanced Energy Materials, 13 (44), Art.-Nr.: 2302525. doi:10.1002/aenm.202302525Anion Storage Chemistry of Organic Cathodes for High‐Energy and High‐Power Density Divalent Metal Batteries

Xiu, Y.; Mauri, A.; Dinda, S.; Pramudya, Y.; Ding, Z.; Diemant, T.; Sarkar, A.; Wang, L.; Li, Z.; Wenzel, W.; Fichtner, M.; Zhao-Karger, Z.

2023. Angewandte Chemie International Edition, 62 (2), Art.: e202212339. doi:10.1002/anie.202212339Conformal Li

Zhang, R.; Ma, Y.; Tang, Y.; Goonetilleke, D.; Diemant, T.; Janek, J.; Kondrakov, A.; Brezesinski, T.

2023. Chemistry of Materials, 35 (17), 6835–6844. doi:10.1021/acs.chemmater.3c01116Identification of Lithium Compounds on Surfaces of Lithium Metal Anode with Machine-Learning-Assisted Analysis of ToF-SIMS Spectra

Zhao, Y.; Otto, S.-K.; Lombardo, T.; Henss, A.; Koeppe, A.; Selzer, M.; Janek, J.; Nestler, B.

2023. ACS Applied Materials & Interfaces, 15 (43), 50469 – 50478. doi:10.1021/acsami.3c09643 -

2022Comparing the Solid Electrolyte Interphases on Graphite Electrodes in K and Li Half Cells

Allgayer, F.; Maibach, J.; Jeschull, F.

2022. ACS applied energy materials, 5 (1), 1136–1148. doi:10.1021/acsaem.1c03491A Roadmap for Transforming Research to Invent the Batteries of the Future Designed within the European Large Scale Research Initiative BATTERY 2030+

Amici, J.; Asinari, P.; Ayerbe, E.; Barboux, P.; Bayle-Guillemaud, P.; Behm, R. J.; Berecibar, M.; Berg, E.; Bhowmik, A.; Bodoardo, S.; Castelli, I. E.; Cekic-Laskovic, I.; Christensen, R.; Clark, S.; Diehm, R.; Dominko, R.; Fichtner, M.; Franco, A. A.; Grimaud, A.; Guillet, N.; Hahlin, M.; Hartmann, S.; Heiries, V.; Hermansson, K.; Heuer, A.; Jana, S.; Jabbour, L.; Kallo, J.; Latz, A.; Lorrmann, H.; Løvvik, O. M.; Lyonnard, S.; Meeus, M.; Paillard, E.; Perraud, S.; Placke, T.; Punckt, C.; Raccurt, O.; Ruhland, J.; Sheridan, E.; Stein, H.; Tarascon, J.-M.; Trapp, V.; Vegge, T.; Weil, M.; Wenzel, W.; Winter, M.; Wolf, A.; Edström, K.

2022. Advanced Energy Materials, 12 (17), Art.-Nr.: 2102785. doi:10.1002/aenm.202102785Comprehensive Approach to Investigate the De‐/Lithiation Mechanism of Fe‐Doped SnO₂ as Lithium‐Ion Anode Material

Asenbauer, J.; Wirsching, A.-L.; Lang, M.; Indris, S.; Eisenmann, T.; Mullaliu, A.; Birrozzi, A.; Hoefling, A.; Geiger, D.; Kaiser, U.; Schuster, R.; Bresser, D.

2022. Advanced Sustainable Systems, 6 (8), Artkl. Nr.: 2200102. doi:10.1002/adsu.202200102Charging sustainable batteries

Bauer, C.; Burkhardt, S.; Dasgupta, N. P.; Ellingsen, L. A.-W.; Gaines, L. L.; Hao, H.; Hischier, R.; Hu, L.; Huang, Y.; Janek, J.; Liang, C.; Li, H.; Li, J.; Li, Y.; Lu, Y.-C.; Luo, W.; Nazar, L. F.; Olivetti, E. A.; Peters, J. F.; Rupp, J. L. M.; Weil, M.; Whitacre, J. F.; Xu, S.

2022. Nature Sustainability, 5 (3), 176–178. doi:10.1038/s41893-022-00864-1High-Throughput Experimentation and Computational Freeway Lanes for Accelerated Battery Electrolyte and Interface Development Research

Benayad, A.; Diddens, D.; Heuer, A.; Krishnamoorthy, A. N.; Maiti, M.; Cras, F. L.; Legallais, M.; Rahmanian, F.; Shin, Y.; Stein, H.; Winter, M.; Wölke, C.; Yan, P.; Cekic-Laskovic, I.

2022. Advanced Energy Materials, 12 (17), Art.Nr.: 2102678. doi:10.1002/aenm.202102678Managing FAIR Tribological Data Using Kadi4Mat

Brandt, N.; Garabedian, N. T.; Schoof, E.; Schreiber, P. J.; Zschumme, P.; Greiner, C.; Selzer, M.

2022. Data, 7 (2), Art.-Nr. 15. doi:10.3390/data7020015Interaction of Mg with the ionic liquid 1-butyl-1-methylpyrrolidinium bis(trifluoromethylsulfonyl)imide—An experimental and computational model study of the electrode–electrolyte interface in post-lithium batteries

Buchner, F.; Forster-Tonigold, K.; Bolter, T.; Rampf, A.; Klein, J.; Groß, A.; Behm, R. J.

2022. Journal of vacuum science & technology / A, 40 (2), Artikel-Nr.: 023204. doi:10.1116/6.0001658Autonomous visual detection of defects from battery electrode manufacturing

Choudhary, N.; Clever, H.; Ludwigs, R.; Rath, M.; Gannouni, A.; Schmetz, A.; Hülsmann, T.; Sawodny, J.; Fischer, L.; Kampker, A.; Fleischer, J.; Stein, H. S.

2022. American Chemical Society (ACS). doi:10.26434/chemrxiv-2022-pvwj3From high‐pressure β‐V 2 O 5 to κ‐Na x V 2 O 5 (x = 0.4 – 0.55): a structural, chemical and kinetic insight into a sodiated phase with a large interlayer space

Córdoba, R.; Goclon, J.; Sarapulova, A.; Fu, Q.; Maibach, J.; Dsoke, S.; Fauth, F.; Kuhn, A.; García-Alvarado, F.

2022. Applied Research, 2 (1), Art.Nr. e202200052. doi:10.1002/appl.202200052Unravelling Charge Carrier Mobility in d₀ ‐Metal‐based Spinels

Dillenz, M.; Sotoudeh, M.; Glaser, C.; Janek, J.; Groß, A.; Euchner, H.

2022. Batteries & Supercaps, 5 (7), Art.-Nr. e202200164. doi:10.1002/batt.202200164Atomistic modeling of Li- and post-Li-ion batteries

Euchner, H.; Groß, A.

2022. Physical Review Materials, 6 (4), Article no: 040302. doi:10.1103/PhysRevMaterials.6.040302Rechargeable Batteries of the Future—The State of the Art from a BATTERY 2030+ Perspective

Fichtner, M.; Edström, K.; Ayerbe, E.; Berecibar, M.; Bhowmik, A.; Castelli, I. E.; Clark, S.; Dominko, R.; Erakca, M.; Franco, A. A.; Grimaud, A.; Horstmann, B.; Latz, A.; Lorrmann, H.; Meeus, M.; Narayan, R.; Pammer, F.; Ruhland, J.; Stein, H.; Vegge, T.; Weil, M.

2022. Advanced Energy Materials, 12 (17), 2102904. doi:10.1002/aenm.202102904Recent Research and Progress in Batteries for Electric Vehicles

Fichtner, M.

2022. Batteries and Supercaps, 5 (2), e202100224. doi:10.1002/batt.202100224First‐Principles Studies on the Atomistic Properties of Metallic Magnesium as Anode Material in Magnesium‐Ion Batteries

Fiesinger, F.; Gaissmaier, D.; Borg, M.; Jacob, T.

2022. ChemSusChem, 15 (14), Art.Nr. e202200414. doi:10.1002/cssc.202200414A Combined XPS and Computational Study of the Chemical Reduction of BMP‐TFSI by Lithium

Forster-Tonigold, K.; Buchner, F.; Bansmann, J.; Behm, R. J.; Groß, A.

2022. Batteries & Supercaps, 5 (12), Art._Nr: e202200484. doi:10.1002/batt.202200484A Combined XPS and Computational Study of the Chemical Reduction of BMP‐TFSI by Lithium

Forster-Tonigold, K.; Buchner, F.; Bansmann, J.; Behm, R. J.; Groß, A.

2022. Batteries and Supercaps, 5 (12), Art.Nr. e202200307. doi:10.1002/batt.202200307Preferred Site Occupation of Doping Cation and Its Impact on the Local Structure of V₂O₅

Fu, Q.; Hansen, A.-L.; Schwarz, B.; Sarapulova, A.; Zhu, L.; Tian, G.; Etter, M.; Missyul, A.; Welter, E.; Murzin, V.; Indris, S.; Azmi, R.; Knapp, M.; Dsoke, S.; Ehrenberg, H.

2022. Chemistry of Materials, 34 (22), 9844–9853. doi:10.1021/acs.chemmater.2c01695High‐Voltage Aqueous Mg‐Ion Batteries Enabled by Solvation Structure Reorganization

Fu, Q.; Wu, X.; Luo, X.; Indris, S.; Sarapulova, A.; Bauer, M.; Wang, Z.; Knapp, M.; Ehrenberg, H.; Wei, Y.; Dsoke, S.

2022. Advanced functional materials, 32 (16), Art.Nr.: 2110674. doi:10.1002/adfm.202110674V₂O₅ as a versatile electrode material for postlithium energy storage systems

Fu, Q.; Zhao, H.; Sarapulova, A.; Dsoke, S.

2022. Applied Research, 2 (3), Art.Nr.: e202200070. doi:10.1002/appl.202200070Detailed Structural and Electrochemical Comparison between High Potential Layered P2-NaMnNi and Doped P2-NaMnNiMg Oxides

Gauckler, C.; Dillenz, M.; Maroni, F.; Pfeiffer, L. F.; Biskupek, J.; Sotoudeh, M.; Fu, Q.; Kaiser, U.; Dsoke, S.; Euchner, H.; Axmann, P.; Wohlfahrt-Mehrens, M.; Groß, A.; Marinaro, M.

2022. ACS Applied Energy Materials, 5 (11), 13735–13750. doi:10.1021/acsaem.2c02402Reversible vs Standard Hydrogen Electrode Scale in Interfacial Electrochemistry from a Theoretician’s Atomistic Point of View

Groß, A.

2022. The Journal of Physical Chemistry C, 126 (28), 11439–11446. doi:10.1021/acs.jpcc.2c02734Ab Initio Simulations of Water/Metal Interfaces

Groß, A.; Sakong, S.

2022. Chemical Reviews, 122 (12), 10746–10776. doi:10.1021/acs.chemrev.1c00679Revisiting the Chevrel Phase: Impact of Dispersion Corrections on the Properties of Mo6S8 for Cathode Applications**

Helmbrecht, K.; Euchner, H.; Groß, A.

2022. Batteries & Supercaps, 5 (8), Art.Nr. e202200002. doi:10.1002/batt.202200002Initial Stages of Sodium Deposition onto Au(111) from [MPPip][TFSI]: An In‐Situ STM Study for Sodium‐Ion Battery Electrolytes

Heubach, M.-K.; Schuett, F. M.; Kibler, L. A.; Abdelrahman, A.; Jacob, T.

2022. ChemElectroChem, 9 (20), Art.Nr.: e202200722. doi:10.1002/celc.202200722Novel Phosphonium-Based Ionic Liquid Electrolytes for Battery Applications

Hofmann, A.; Rauber, D.; Wang, T.-M.; Hempelmann, R.; Kay, C. W. M.; Hanemann, T.

2022. Molecules, 27 (15), Art.Nr.: 4729. doi:10.3390/molecules27154729Dataset of propylene carbonate based liquid electrolyte mixtures for sodium-ion cells

Hofmann, A.; Wang, Z.; Bautista, S. P.; Weil, M.; Müller, F.; Löwe, R.; Schneider, L.; Mohsin, I. U.; Hanemann, T.

2022. Data in Brief, 40, Article no: 107775. doi:10.1016/j.dib.2021.107775Advancing the Sustainability of Batteries. A Tongji University/Nature Sustainability Expert Panel Report

Huang, Y.; Bauer, C.; Burkhardt, S.; Dasgupta, N. P.; Ellingsen, L. A.-W.; Gaines, L. L.; Hao, H.; Hischier, R.; Hu, L.; Huang, Y.-M.; Janek, J.; Liang, C.; Li, H.; Li, J.; Li, Y.; Lu, Y.-C.; Luo, W.; Nazar, L. F.; Olivetti, E. A.; Peters, J. F.; Rupp, J. L. M.; Weil, M.; Whitacre, J. F.; Xu, S.

2022. Tongji UniversityDevelopment of Magnesium Borate Electrolytes: Explaining the Success of Mg[B(hfip)4]2 Salt

Jankowski, P.; Li, Z.; Zhao-Karger, Z.; Diemant, T.; Fichtner, M.; Vegge, T.; Lastra, J. M. G.

2022. Energy storage materials, 45, 1133–1143. doi:10.1016/j.ensm.2021.11.012Poly(ethylene oxide)-Based Electrolytes for Solid-State Potassium Metal Batteries with a Prussian Blue Positive Electrode

Khudyshkina, A. D.; Morozova, P. A.; Butzelaar, A. J.; Hoffmann, M.; Wilhelm, M.; Theato, P.; Fedotov, S. S.; Jeschull, F.

2022. ACS Applied Polymer Materials, 4 (4), 2734–2746. doi:10.1021/acsapm.2c00014Drying of NCM Cathode Electrodes with Porous, Nanostructured Particles Versus Compact Solid Particles: Comparative Study of Binder Migration as a Function of Drying Conditions

Klemens, J.; Schneider, L.; Herbst, E. C.; Bohn, N.; Müller, M.; Bauer, W.; Scharfer, P.; Schabel, W.

2022. Energy technology, 10 (4), Article no: 2100985. doi:10.1002/ente.202100985Simulation-Based and Data-Driven Techniques for Quantifying the Influence of the Carbon Binder Domain on Electrochemical Properties of Li-Ion Batteries

Knorr, T.; Hein, S.; Prifling, B.; Neumann, M.; Danner, T.; Schmidt, V.; Latz, A.

2022. Energies, 15 (21), Art.-Nr.: 7821. doi:10.3390/en15217821The interfacial structure of InP(100) in contact with HCl and H2SO4 studied by reflection anisotropy spectroscopy

Löw, M.; Guidat, M.; Kim, J.; May, M. M.

2022. RSC Advances, 12 (50), 32756–32764. doi:10.1039/D2RA05159AResolving the Role of Configurational Entropy in Improving Cycling Performance of Multicomponent Hexacyanoferrate Cathodes for Sodium‐Ion Batteries

Ma, Y.; Hu, Y.; Pramudya, Y.; Diemant, T.; Wang, Q.; Goonetilleke, D.; Tang, Y.; Zhou, B.; Hahn, H.; Wenzel, W.; Fichtner, M.; Ma, Y.; Breitung, B.; Brezesinski, T.

2022. Advanced Functional Materials, 32 (34), Art.Nr. 2202372. doi:10.1002/adfm.202202372Advances in Nanomaterials for Lithium-Ion/Post-Lithium-Ion Batteries and Supercapacitors

Marinaro, M.; Dsoke, S.

2022. Nanomaterials, 12 (15), Art.Nr. 2512. doi:10.3390/nano12152512Sodiation of hard carbon: how separating enthalpy and entropy contributions can find transitions hidden in the voltage profile

Mercer, M.; Affleck, S.; Gavilan-Arriazu, E. M.; Zulke, A. A.; Maughan, P. A.; Trivedi, S.; Fichtner, M.; Reddy Munnangi, A.; Leiva, E. P. M.; Hoster, H. E.

2022. ChemPhysChem, 23 (5), e202100748. doi:10.1002/cphc.202100748Heat generation and degradation mechanisms studied on Na₃V₂(PO₄)₃/C positive electrode material in full pouch / coin cell assembly

Mohsin, I. U.; Schneider, L.; Häringer, M.; Ziebert, C.; Rohde, M.; Bauer, W.; Ehrenberg, H.; Seifert, H. J.

2022. Journal of Power Sources, 545, Art.-Nr.: 231901. doi:10.1016/j.jpowsour.2022.2319013D microstructure characterization of polymer battery electrodes by statistical image analysis based on synchrotron X-ray tomography

Neumann, M.; Ademmer, M.; Osenberg, M.; Hilger, A.; Wilde, F.; Muench, S.; Hager, M. D.; Schubert, U. S.; Manke, I.; Schmidt, V.

2022. Journal of Power Sources, 542, 231783. doi:10.1016/j.jpowsour.2022.231783Classification of FIB/SEM-tomography images for highly porous multiphase materials using random forest classifiers

Osenberg, M.; Hilger, A.; Neumann, M.; Wagner, A.; Bohn, N.; Binder, J. R.; Schmidt, V.; Banhart, J.; Manke, I.

2022. arxiv. doi:10.48550/arXiv.2207.14114Layered P2-Na

Pfeiffer, L. F.; Jobst, N.; Gauckler, C.; Lindén, M.; Marinaro, M.; Passerini, S.; Wohlfahrt-Mehrens, M.; Axmann, P.

2022. Frontiers in Energy Research, 10, Art.-Nr.: 910842. doi:10.3389/fenrg.2022.910842Visualization of structural changes and degradation of porphyrin-based battery electrodes

Philipp, T.; Neusser, G.; Abouzari-Lotf, E.; Shakouri, S.; Wilke, F. D. H.; Fichtner, M.; Ruben, M.; Mundszinger, M.; Biskupek, J.; Kaiser, U.; Scheitenberger, P.; Lindén, M.; Kranz, C.

2022. Journal of Power Sources, 522, Art.-Nr.: 231002. doi:10.1016/j.jpowsour.2022.231002Quantitative Comparison of Different Approaches for Reconstructing the Carbon‐Binder Domain from Tomographic Image Data of Cathodes in Lithium‐Ion Batteries and Its Influence on Electrochemical Properties

Prifling, B.; Neumann, M.; Hein, S.; Danner, T.; Heider, E.; Hoffmann, A.; Rieder, P.; Hilger, A.; Osenberg, M.; Manke, I.; Wohlfahrt-Mehrens, M.; Latz, A.; Schmidt, V.

2022. Energy Technology, Art.-Nr.: 2200784. doi:10.1002/ente.202200784Enabling Modular Autonomous Feedback-Loops in Materials Science through Hierarchical Experimental Laboratory Automation and Orchestration

Rahmanian, F.; Flowers, J.; Guevarra, D.; Richter, M.; Fichtner, M.; Donnely, P.; Gregoire, J. M.; Stein, H. S.

2022. Advanced Materials Interfaces, 8 (9), 2101987. doi:10.1002/admi.202101987One-shot active learning for globally optimal battery electrolyte conductivity

Rahmanian, F.; Vogler, M.; Wölke, C.; Yan, P.; Winter, M.; Cekic-Laskovic, I.; Stein, H. S.

2022. American Chemical Society (ACS). doi:10.26434/chemrxiv-2022-1z8gnInvestigation of the Anode-Electrolyte Interface in a Magnesium Full-Cell with Fluorinated Alkoxyborate-Based Electrolyte

Roy, A.; Bhagavathi Parambath, V.; Diemant, T.; Neusser, G.; Kranz, C.; Behm, R. J.; Li, Z.; Zhao-Karger, Z.; Fichtner, M.

2022. Batteries and Supercaps, 5 (4), Art.-Nr.: e202100305. doi:10.1002/batt.202100305Transport Properties in Electrodes for Lithium-Ion Batteries: Comparison of Compact versus Porous NCM Particles

Schneider, L.; Klemens, J.; Herbst, E. C.; Müller, M.; Scharfer, P.; Schabel, W.; Bauer, W.; Ehrenberg, H.

2022. Journal of The Electrochemical Society, 169 (10), Art.-Nr.: 100553. doi:10.1149/1945-7111/ac9c37Suitability of Carbazolyl Hauser and Turbo‐Hauser Bases as Magnesium‐Based Electrolytes

Schüler, P.; Sengupta, S.; Zaubitzer, S.; Fiesinger, F.; Dongmo, S.; Görls, H.; Wohlfahrt-Mehrens, M.; Borg, M.; Gaissmaier, D.; Krieck, S.; Marinaro, M.; Jacob, T.; Westerhausen, M.

2022. European Journal of Inorganic Chemistry, 2022 (17), Art.-Nr.: e202200149. doi:10.1002/ejic.202200149Stability of magnesium binary and ternary compounds for batteries determined from first principles

Sotoudeh, M.; Gross, A.

2022. American Chemical Society (ACS). doi:10.26434/chemrxiv-2022-m90n5Descriptor and Scaling Relations for Ion Mobility in Crystalline Solids

Sotoudeh, M.; Groß, A.

2022. JACS Au, 2 (2), 463–471. doi:10.1021/jacsau.1c00505Advancing data-driven chemistry by beating benchmarks

Stein, H. S.

2022. Trends in Chemistry, 4 (8), 682–684. doi:10.1016/j.trechm.2022.05.003From materials discovery to system optimization by integrating combinatorial electrochemistry and data science

Stein, H. S.; Sanin, A.; Rahmanian, F.; Zhang, B.; Vogler, M.; Flowers, J. K.; Fischer, L.; Fuchs, S.; Choudhary, N.; Schroeder, L.

2022. Current Opinion in Electrochemistry, 35, Art.-Nr.: 101053. doi:10.1016/j.coelec.2022.101053Brokering between tenants for an international materials acceleration platform

Vogler, M.; Busk, J.; Hajiyani, H.; Jørgensen, P. B.; Safaei, N.; Castelli, I.; Ramírez, F. F.; Carlsson, J.; Pizzi, G.; Clark, S.; Hanke, F.; Bhowmik, A.; Stein, H. S.

2022. American Chemical Society (ACS). doi:10.26434/chemrxiv-2022-grgrdP2-type layered high-entropy oxides as sodium-ion cathode materials

Wang, J.; Dreyer, S. L.; Wang, K.; Ding, Z.; Diemant, T.; Karkera, G.; Ma, Y.; Sarkar, A.; Zhou, B.; Gorbunov, M. V.; Omar, A.; Mikhailova, D.; Presser, V.; Fichtner, M.; Hahn, H.; Brezesinski, T.; Breitung, B.; Wang, Q.

2022. Materials Futures, 1 (3), Art.Nr. 035104. doi:10.1088/2752-5724/ac8ab9Ionic Liquid‐Incorporated Metal‐Organic Framework with High Magnesium Ion Conductivity for Quasi‐Solid‐State Magnesium Batteries

Wei, Z.; Maile, R.; Riegger, L. M.; Rohnke, M.; Müller-Buschbaum, K.; Janek, J.

2022. Batteries & Supercaps, 5 (12), Art.-Nr.: e202200318. doi:10.1002/batt.202200318A Novel and Highly Efficient Indolyl‐Based Electrolyte for Mg Batteries

Zaubitzer, S.; Dongmo, S.; Schüler, P.; Krieck, S.; Fiesinger, F.; Gaissmaier, D.; van den Borg, M.; Jacob, T.; Westerhausen, M.; Wohlfahrt-Mehrens, M.; Marinaro, M.

2022. Energy Technology, 10 (8), Art.-Nr.: 2200440. doi:10.1002/ente.202200440Robotic cell assembly to accelerate battery research

Zhang, B.; Fischer, L.; Sanin, A.; Stein, H. S.

2022. American Chemical Society (ACS). doi:10.26434/chemrxiv-2022-vt2n9Combined Thermal Runaway Investigation of Coin Cells with an Accelerating Rate Calorimeter and a Tian-Calvet Calorimeter

Zhao, W.; Rohde, M.; Mohsin, I. U.; Ziebert, C.; Du, Y.; Seifert, H. J.

2022. Batteries, 8 (2). doi:10.3390/batteries8020015Study on Na₂V₀

Zhao, Z.; Darma, M. S. D.; Tian, G.; Luo, X.; Zhao, E.; Wang, B.-T.; Zhao, J.; Hua, W.; Zhao, X.; Wang, Y.; Ehrenberg, H.; Dsoke, S.

2022. Chemical Engineering Journal, 444, Article no: 136608. doi:10.1016/j.cej.2022.136608Calcium-tin alloys as anodes for rechargeable non-aqueous calcium-ion batteries at room temperature

Zhao-Karger, Z.; Xiu, Y.; Li, Z.; Reupert, A.; Smok, T.; Fichtner, M.

2022. Nature Communications, 13 (1), 3849. doi:10.1038/s41467-022-31261-z -

2021A Self-Conditioned Metalloporphyrin as a Highly Stable Cathode for Fast Rechargeable Magnesium Batteries

Abouzari-Lotf, E.; Azmi, R.; Li, Z.; Shakouri, S.; Chen, Z.; Zhao-Karger, Z.; Klyatskaya, S.; Maibach, J.; Ruben, M.; Fichtner, M.

2021. ChemSusChem, 14 (8), 1840–1846. doi:10.1002/cssc.202100340Na₃V₂(PO₄)₃ - A Highly Promising Anode and Cathode Material for Sodium-Ion Batteries

Akçay, T.; Häringer, M.; Pfeifer, K.; Anhalt, J.; Binder, J. R.; Dsoke, S.; Kramer, D.; Mönig, R.

2021. ACS applied energy materials, 4 (11), 12688–12695. doi:10.1021/acsaem.1c02413Molecular Vanadium Oxides for Energy Conversion and Energy Storage: Current Trends and Emerging Opportunities

Anjass, M.; Lowe, G. A.; Streb, C.

2021. Angewandte Chemie / International edition, 60 (14), 7522–7532. doi:10.1002/anie.202010577A Brief review of supercapacitors as a novel energy storage device

Bahmei, F.; Bahramifar, N.; Ghasemi, S.; Younesi, H.; Weil, M.

2021. Fuel, ElsevierComparative patent analysis for the identification of global research trends for the case of battery storage, hydrogen and bioenergy

Baumann, M.; Domnik, T.; Haase, M.; Wulf, C.; Emmerich, P.; Rösch, C.; Zapp, P.; Naegler, T.; Weil, M.

2021. Technological forecasting and social change, 165, Art.-Nr.: 120505. doi:10.1016/j.techfore.2020.120505Prospective Life Cycle Assessment of a Model Magnesium Battery

Bautista, S. P.; Weil, M.; Baumann, M.; Tomasini Montenegro, C.

2021. Energy technology, 9 (4), Art.-Nr. 2000964. doi:10.1002/ente.202000964Density Functional Theory Studies on Sulfur-Polyacrylonitrile as a Cathode Host Material for Lithium-Sulfur Batteries

Bertolini, S.; Jacob, T.

2021. ACS Omega, 6 (14), 9700–9708. doi:10.1021/acsomega.0c06240Sodium Cyclopentadienide as a New Type of Electrolyte for Sodium Batteries

Binder, M.; Mandl, M.; Zaubitzer, S.; Wohlfahrt-Mehrens, M.; Passerini, S.; Böse, O.; Danzer, M. A.; Marinaro, M.

2021. ChemElectroChem, 8 (2), 365–369. doi:10.1002/celc.202001290Electrochemical Modeling of Hierarchically Structured Lithium‐Ion Battery Electrodes

Birkholz, O.; Kamlah, M.

2021. Energy technology, 9 (6), Art.-Nr.: 2000910. doi:10.1002/ente.202000910Theoretical studies on the initial oxidation of metallic lithium anodes

Borg, M. van den; Gaissmaier, D.; Knobbe, E.; Fantauzzi, D.; Jacob, T.

2021. Applied Surface Science, 555, Art.-Nr.: 149447. doi:10.1016/j.apsusc.2021.149447Mitigating self-discharge and improving the performance of Mg–S battery in Mg[B(hfip)

Bosubabu, D.; Li, Z.; Meng, Z.; Wang, L.-P.; Fichtner, M.; Zhao-Karger, Z.

2021. Journal of materials chemistry / A, 9 (44), 25150–25159. doi:10.1039/D1TA06114CKadi4Mat : A Research Data Infrastructure for Materials Science

Brandt, N.; Griem, L.; Herrmann, C.; Schoof, E.; Tosato, G.; Zhao, Y.; Zschumme, P.; Selzer, M.

2021. Data science journal, 20 (1), Art.-Nr.: 8. doi:10.5334/dsj-2021-008UHV preparation and electrochemical/-catalytic properties of well-defined Co– and Fe-containing unary and binary oxide model cathodes for the oxygen reduction and oxygen evolution reaction in Zn-air batteries

Buchner, F.; Fuchs, S.; Behm, R. J.

2021. Journal of electroanalytical chemistry, 896, 115497. doi:10.1016/j.jelechem.2021.115497The potential of scanning electrochemical probe microscopy and scanning droplet cells in battery research

Daboss, S.; Rahmanian, F.; Stein, H. S.; Kranz, C.

2021. Electrochemical Science Advances, 2 (4), e2100122. doi:10.1002/elsa.202100122Multiphase-field modeling of spinodal decomposition during intercalation in an Allen-Cahn framework

Daubner, S.; Kubendran Amos, P. G.; Schoof, E.; Santoki, J.; Schneider, D.; Nestler, B.

2021. Physical review materials, 5 (3), Article no: 035406. doi:10.1103/PhysRevMaterials.5.035406On the Electrochemical Insertion of Mg2+in Na7V4(P2O7)4(PO4) and Na3V2(PO4)3 Host Materials

Dongmo, S.; Maroni, F.; Gauckler, C.; Marinaro, M.; Wohlfahrt-Mehrens, M.

2021. Journal of the Electrochemical Society, 168 (12), Art. Nr.: 120541. doi:10.1149/1945-7111/ac412bModeling of Electron‐Transfer Kinetics in Magnesium Electrolytes: Influence of the Solvent on the Battery Performance

Drews, J.; Jankowski, P.; Häcker, J.; Li, Z.; Danner, T.; García Lastra, J. M.; Vegge, T.; Wagner, N.; Friedrich, K. A.; Zhao-Karger, Z.; Fichtner, M.; Latz, A.

2021. ChemSusChem, 14 (21), 4820–4835. doi:10.1002/cssc.202101498An affordable option to Au single crystals through cathodic corrosion of a wire: Fabrication, electrochemical behavior, and applications in electrocatalysis and spectroscopy

Elnagar, M. M.; Hermann, J. M.; Jacob, T.; Kibler, L. A.

2021. Electrochimica acta, 372, 137867. doi:10.1016/j.electacta.2021.137867Energy Flow Analysis of Laboratory Scale Lithium-Ion Battery Cell Production

Erakca, M.; Baumann, M.; Bauer, W.; Biasi, L. de; Hofmann, J.; Bold, B.; Weil, M.

2021. iScience, 24 (5), Article: 102437. doi:10.1016/j.isci.2021.102437Model Studies on the Formation of the Solid Electrolyte Interphase: Reaction of Li with Ultrathin Adsorbed Ionic-Liquid Films and Co

Forster-Tonigold, K.; Kim, J.; Bansmann, J.; Groß, A.; Buchner, F.

2021. ChemPhysChem, 22 (5), 441–454. doi:10.1002/cphc.202001033In operando study of orthorhombic V₂O₅ as positive electrode materials for K-ion batteries

Fu, Q.; Sarapulova, A.; Zhu, L.; Melinte, G.; Missyul, A.; Welter, E.; Luo, X.; Knapp, M.; Ehrenberg, H.; Dsoke, S.

2021. Journal of Energy Chemistry, 62, 627–636. doi:10.1016/j.jechem.2021.04.027Electrochemical performance and reaction mechanism investigation of V₂O₅ positive electrode material for aqueous rechargeable zinc batteries

Fu, Q.; Wang, J.; Sarapulova, A.; Zhu, L.; Missyul, A.; Welter, E.; Luo, X.; Ding, Z.; Knapp, M.; Ehrenberg, H.; Dsoke, S.

2021. Journal of materials chemistry / A, 9 (31), 16776–16786. doi:10.1039/D1TA03518ESupramolecular assembly of a hierarchically structured 3D potassium vanadate framework

Greiner, S.; Anjass, M.; Streb, C.

2021. CrystEngComm, 23 (22), 3946–3950. doi:10.1039/d1ce00661dIron-based perovskites-reduced graphene oxide as possible cathode materials for rechargeable iron-ion battery

Hassan, H. K.; Galal, A.; Atta, N. F.; Jacob, T.

2021. Journal of Alloys and Compounds, 870, Art.-Nr.: 159383. doi:10.1016/j.jallcom.2021.159383Accelerated Kinetics Revealing Metastable Pathways of Magnesiation-Induced Transformations in MnO

Hatakeyama, T.; Li, H.; Okamoto, N. L.; Shimokawa, K.; Kawaguchi, T.; Tanimura, H.; Imashuku, S.; Fichtner, M.; Ichitsubo, T.

2021. Chemistry of Materials, 33 (17), 6983–6996. doi:10.1021/acs.chemmater.1c02011Multiphase-field model for surface diffusion and attachment kinetics in the grand-potential framework

Hoffrogge, P. W.; Mukherjee, A.; Nani, E. S.; Amos, P. G. K.; Wang, F.; Schneider, D.; Nestler, B.

2021. Physical review / E, 103 (3), Article no: 033307. doi:10.1103/PhysRevE.103.033307Comprehensive characterization of propylene carbonate based liquid electrolyte mixtures for sodium-ion cells

Hofmann, A.; Wang, Z.; Bautista, S. P.; Weil, M.; Müller, F.; Löwe, R.; Schneider, L.; Mohsin, I. U.; Hanemann, T.

2021. Electrochimica acta, 403, Art.Nr.: 139670. doi:10.1016/j.electacta.2021.139670Investigation of Parameters Influencing the Producibility of Anodes for Sodium-Ion Battery Cells

Hofmann, J.; Wurba, A.-K.; Bold, B.; Maliha, S.; Schollmeyer, P.; Fleischer, J.; Klemens, J.; Scharfer, P.; Schabel, W.

2021. Production at the leading edge of technology – Proceedings of the 10th Congress of the German Academic Association for Production Technology (WGP), Dresden, 23-24 September 2020. Ed.: B.-A. Behrens, 171–181, Springer. doi:10.1007/978-3-662-62138-7_18Polyoxometalate Modified Separator for Performance Enhancement of Magnesium–Sulfur Batteries

Ji, Y.; Liu-Théato, X.; Xiu, Y.; Indris, S.; Njel, C.; Maibach, J.; Ehrenberg, H.; Fichtner, M.; Zhao-Karger, Z.

2021. Advanced Functional Materials, 31 (26), Art.-Nr.: 2100868. doi:10.1002/adfm.202100868Online adaptive quantum characterization of a nuclear spin

Joas, T.; Schmitt, S.; Santagati, R.; Gentile, A. A.; Bonato, C.; Laing, A.; McGuinness, L. P.; Jelezko, F.

2021. npj Quantum information, 7 (1), 56. doi:10.1038/s41534-021-00389-zPerformance Study of MXene/Carbon Nanotube Composites for Current Collector‐ and Binder‐Free Mg–S Batteries

Kaland, H.; Håskjold Fagerli, F.; Hadler-Jacobsen, J.; Zhao-Karger, Z.; Fichtner, M.; Wiik, K.; Wagner, N. P.